Introduction to Stepping bottom quenching and tempering furnace, forging furnace specifications, model parameters

Stepping bottom quenching and tempering furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,Commonly used inMetal tempering,Energy conservation and environmental protection,Improve production efficiency,Metal tempering,Metal heat treatment and so on,customizable。The following is to introduce the Stepping bottom quenching and tempering furnace:

1、Brief introduction of Stepping bottom quenching and tempering furnace

Stepping bottom quenching and tempering furnaceIt is a forging heating device using gas as fuel.,it has the functions of heat treatment, hardening and tempering, normalizing, Casting heating and normalizing,the main features are Easy to maintain, Stable and reliable, energy-efficient, Strong adaptability and Easy to control,it mainly includes Radiation chamber, convection chamber, ventilation system, furnace chamber and Radiation chamber,This Stepping bottom quenching and tempering furnaceSimple structure and advanced technology.,is a common Stepping bottom quenching and tempering furnace。

Stepping bottom quenching and tempering furnace

2、Advantages of Stepping bottom quenching and tempering furnace principle

Stepping bottom quenching and tempering furnaceat work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,features include Easy to maintain, Easy to control, energy saving and environmental protection, energy-efficient and Strong adaptability,be loved by our customers.。

Stepping bottom quenching and tempering furnace

3、Stepping bottom quenching and tempering furnace function

Stepping bottom quenching and tempering furnaceit has the functions of heat treatment, temper, anneal, quench and hardening and tempering,it is widely used in Machinery manufacturing, automobile, building materials, metallurgy and petroleum,at runtime,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,is designed by One-combustion energy saving with advanced technology。

Stepping bottom quenching and tempering furnace

4、Stepping bottom quenching and tempering furnace structure

The Stepping bottom quenching and tempering furnace structure is introduced as follows:

- ventilation system

- Waste heat recovery system

- combustor

- Radiation chamber

- ventilation system

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The heat load of the main place for Stepping bottom quenching and tempering furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Stepping bottom quenching and tempering furnace

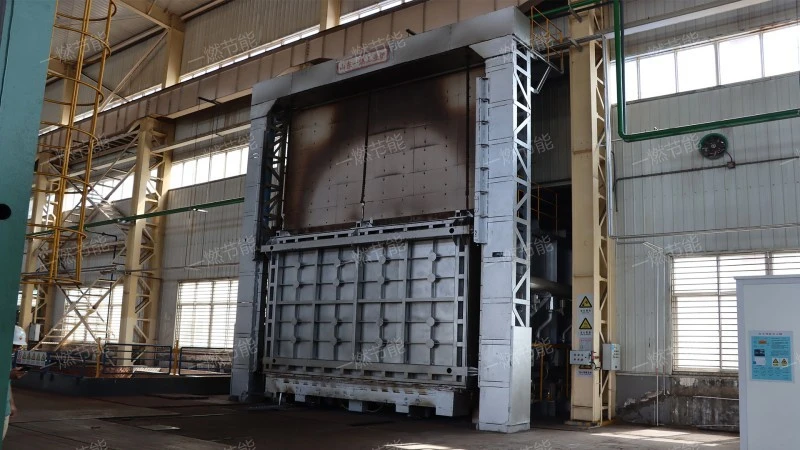

5、Stepping bottom quenching and tempering furnace field real shot

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the Stepping bottom quenching and tempering furnace production process and production site, and gain favorable comments and recognition from customers.。

Stepping bottom quenching and tempering furnace

As you can see from the live video.,One-combustion energy saving at the start of the operation,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

6、Company preferential activities

Stepping bottom quenching and tempering furnace is a new type of forging furnace introduced by Shandong yiran energy-saving environment protection co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for aerospace and other industries. Now consult One-combustion energy savingproduction-manufacturing的Stepping bottom quenching and tempering furnace, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Stepping bottom quenching and tempering furnaceit has the characteristics of Stable and reliable, Easy to maintain, energy saving and environmental protection, energy-efficient and Strong adaptability,Widely used inMetal forging heating,Metal melting and casting,Energy conservation and environmental protection,Metal forging heating,Metal melting and casting and so on,it has the structure of recovery of waste heat, ventilation system, combustor, furnace chamber and ventilation system。

Related recommendation

-

Introduction to Automatic trolley heating furnace and heating furnace structure principle

2025-5-27 -

What is a Segmented annealing heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Automatic greenhouse furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

Introduction to Gas storage through forging furnace and forging furnace working principle

2025-5-27 -

Introduction to Quenching deep well furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Low temperature tube annealing furnace and forging furnace working principle

2025-5-27 -

井式台车锻造加热炉

2023-09-10 -

Introduction to Industrial energy-saving resistance furnace, introduction to Trolley resistance furnace function advantages and characteristics

2025-5-27 -

调质台车锻造加热炉

2023-08-05 -

Introduction to Stepped tube billet heating furnace, advantages, characteristics and principles of heating furnace

2025-5-27