Introduction to Quenching deep well furnace and forging furnace advantages and features

Quenching deep well furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the product looks beautiful.,the advantage is Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.,widely used in pharmacy, automobile, electron, petroleum, Household necessities and other fields,at the start of the operation,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.。The following is to introduce the Quenching deep well furnace:

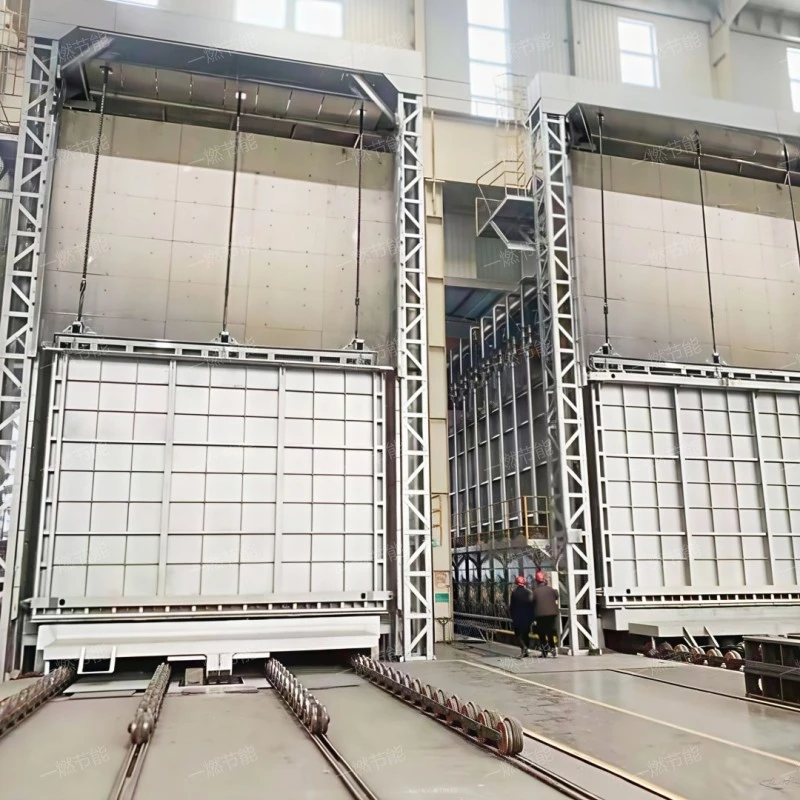

1、Brief introduction of Quenching deep well furnace

Quenching deep well furnaceIt is a forging heating device using gas as fuel.,it has the characteristics of Easy to maintain, energy saving and environmental protection, Strong adaptability, Easy to control and Easy to maintain。

Quenching deep well furnace

2、Quenching deep well furnace function

Quenching deep well furnaceit has the functions of heat treatment, anneal, temper, Casting heating and temper,has been favored by more and more customers.。

Quenching deep well furnace

3、Structural characteristics of Quenching deep well furnace

The Quenching deep well furnace structure is introduced as follows:

- combustor

- Waste heat recovery system

- convection chamber

- ventilation system

- Waste heat recovery system

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The material is heated by convection heat transfer of high temperature flue gas discharged from the radiation chamber. Flue gas washes the tube wall of the furnace tube at a high speed to carry out effective convection heat transfer, and its heat load accounts for about 20%-30% of the whole furnace. The convection chamber is generally arranged above the radiation chamber, and some are placed on the ground alone. In order to improve the heat transfer effect, nail head tubes or finned tubes are often used in furnace tubes.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

Quenching deep well furnace

4、Quenching deep well furnace principle

Quenching deep well furnacethe principle is simple.The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,it is widely used in material, war industry, Machinery manufacturing, building materials, heat treatment and other industries,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

Quenching deep well furnace

5、Quenching deep well furnace quotation

The Quenching deep well furnace price is introduced as follows:

- product configuration

- Manufacturer scale

- raw material

- Reasonable sales model

- service

The difference in Quenching deep well furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Reliable manufacturers can produce excellent products, and such manufacturers have high comprehensive credibility and can design products in all directions. Therefore, compared with other manufacturers, such products have higher scientific and technological content and more functions. One-combustion energy saving's reputation and products are very high, and it is a trustworthy big brand and manufacturer.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Quenching deep well furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Quenching deep well furnace price can meet the purchasing needs of customers.

Quenching deep well furnace

6、One-combustion energy saving's after-sales service

Our company One-combustion energy saving is not only good in product quality, but also professional in service, which can provide customers with high-standard services and tailor products according to their on-site construction conditions to ensure that they can meet their different needs. In addition, our company also carries out on-site product installation and debugging for customers, and trains staff on product operation knowledge and precautions, in order to make them operate products better and prolong the service life of products. In addition, if you have other questions, you can click on the online consultation, and a professional will answer them for you.。

One-combustion energy saving

Quenching deep well furnacethe product looks atmospheric.,Widely used in Metal melting and casting, Metal heat treatment, Metal forging heating, Energy conservation and environmental protection and Metal tempering,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Related recommendation

-

台车式循环炉

2023-06-28 -

Introduction to Environmentally friendly tubular heating furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Split type trolley heating furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

Introduction to Electric forging heating furnace, advantages, characteristics and principles of Trolley electric furnace

2025-5-27 -

What is a Electric heating bright annealing furnace? Introduction to the advantages, characteristics, and principles of the Trolley resistance heating furnace

2025-5-27 -

What is a Regenerative burner roller bottom furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

Introduction to Automatic high-temperature trolley forging heating furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Square Well Heating Furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Continuous decarbonization annealing heat treatment furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Double ended trolley resistance furnace, introduction to Trolley resistance furnace function advantages and characteristics

2025-5-27