What is a Continuous spheroidization annealing industrial furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

Continuous spheroidization annealing industrial furnaceIt is a forging heating device using gas as fuel.,it has the characteristics of Strong adaptability, Easy to control, Stable and reliable, Strong adaptability and Easy to control。

1、Brief introduction of Continuous spheroidization annealing industrial furnace

Continuous spheroidization annealing industrial furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,generally, it is composed of convection chamber, furnace chamber, ventilation system, recovery of waste heat, furnace chamber and other major components,productThe overall structural design is relatively simple。

Continuous spheroidization annealing industrial furnace

2、Continuous spheroidization annealing industrial furnace video detail

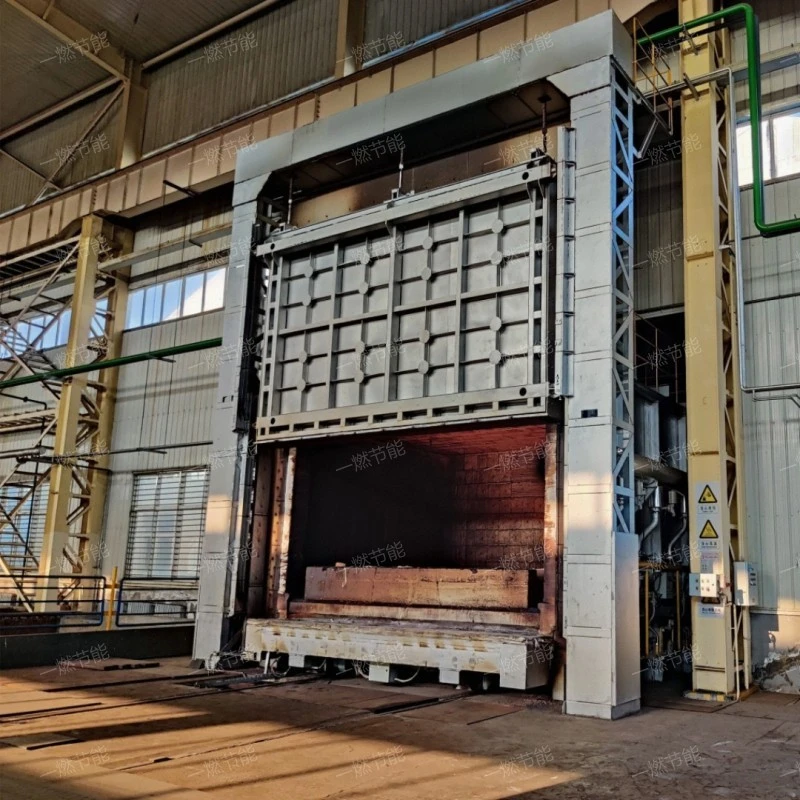

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Continuous spheroidization annealing industrial furnacet operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Continuous spheroidization annealing industrial furnace

As you can see from the live video.,One-combustion energy saving It has a wide range of uses, and is often used inMetal melting and casting,Improve production efficiency,Metal tempering,Energy conservation and environmental protection,Metal forging heating and so on。

3、Working principle of Continuous spheroidization annealing industrial furnace

Continuous spheroidization annealing industrial furnacein the course of work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,It is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。

Continuous spheroidization annealing industrial furnace

4、Structural advantages of Continuous spheroidization annealing industrial furnace

The Continuous spheroidization annealing industrial furnace has the following structure

- convection chamber

- ventilation system

- Radiation chamber

- combustor

- combustor

The material is heated by convection heat transfer of high temperature flue gas discharged from the radiation chamber. Flue gas washes the tube wall of the furnace tube at a high speed to carry out effective convection heat transfer, and its heat load accounts for about 20%-30% of the whole furnace. The convection chamber is generally arranged above the radiation chamber, and some are placed on the ground alone. In order to improve the heat transfer effect, nail head tubes or finned tubes are often used in furnace tubes.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The heat load of the main place for Continuous spheroidization annealing industrial furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Continuous spheroidization annealing industrial furnace

5、How much is the Continuous spheroidization annealing industrial furnace?

The Continuous spheroidization annealing industrial furnace price is introduced as follows:

- Model size

- sales mode

- Overall configuration

- select a qualified person

- brand

The same type of products, with different specifications, models and sizes, have different costs, so the quotations to customers naturally vary. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. One-combustion energy saving has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

Different brands of products in the same series have more or less differences in product prices, and different brands of Continuous spheroidization annealing industrial furnace have more or less differences in price.

Continuous spheroidization annealing industrial furnace

6、One-combustion energy saving delivery site

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Continuous spheroidization annealing industrial furnacet operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Continuous spheroidization annealing industrial furnace

As you can see from the live video.One-combustion energy saving It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Continuous spheroidization annealing industrial furnacethe main features are energy saving and environmental protection, Easy to maintain, Stable and reliable, energy-efficient and Strong adaptability,widely used in material, building materials, aerospace, surface treatment, light industry and other fields。

Related recommendation

-

What is a Step furnace flue gas denitrification? Introduction to the advantages and characteristics of the SCR denitration

2025-5-27 -

What is a Dual heat storage stepper industrial furnace? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to Automatic temperature control resistance heating furnace, Trolley resistance furnace specifications, model parameters

2025-5-27 -

Introduction to Trolley heating furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Combination walking back and forth furnace and Forging furnace structure principle

2025-5-27 -

What is a Trolley type low-temperature heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Stepping bottom tube billet heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

井式燃气台车炉

2023-09-12 -

Introduction to Two end high-temperature natural gas trolley furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Car positive furnace, Forging furnace specifications, model parameters

2025-5-27