Introduction to Steel ingot heating furnace and heating furnace working principle

Steel ingot heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,Easy to maintain,Strong adaptability,Easy to control,Easy to maintain,Strong adaptability,at work,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.。

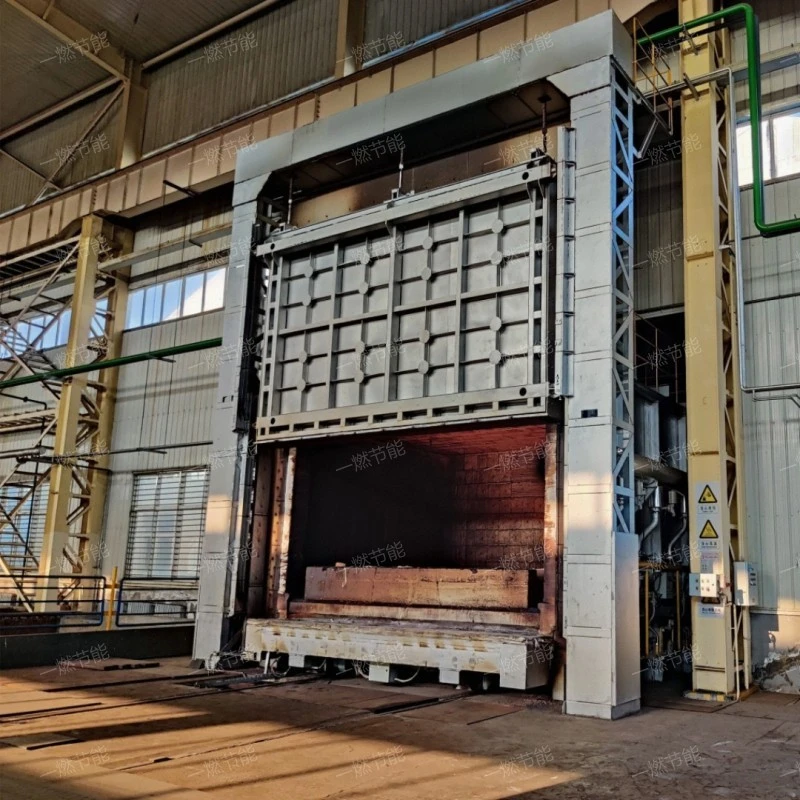

1、Brief introduction of Steel ingot heating furnace

Steel ingot heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,support customization。

Steel ingot heating furnace

2、Steel ingot heating furnace display

High-definition picture display of Steel ingot heating furnace, excellent material selection, reliable quality and trustworthy.。

Steel ingot heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Steel ingot heating furnace structure

The Steel ingot heating furnace structure is introduced as follows:

- Radiation chamber

- furnace chamber

- convection chamber

- combustor

- ventilation system

The heat load of the main place for Steel ingot heating furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Steel ingot heating furnace

4、Steel ingot heating furnace video detail

Speak directly with facts on the spot。

Steel ingot heating furnace

As you can see from the live video.,One-combustion energy saving the advantage is Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Adopting advanced combustion technology and materials, it has a long service life and low maintenance cost.。

5、Steel ingot heating furnace price

The Steel ingot heating furnace price is introduced as follows:

- Company size

- brand

- geographical position

- Manufacturer's sales model

- After-sales service level

Our factory is a direct selling manufacturer of Steel ingot heating furnace, with independent production and processing facilities, few circulation links and low circulation cost.

Different brands of products in the same series have more or less differences in product prices, and different brands of Steel ingot heating furnace have more or less differences in price.

One-combustion energy saving address:Jinan, the transportation here is developed and convenient, and the products can be transported to the designated place in a short time, which saves customers a sum of transportation expenses.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Steel ingot heating furnace price and service can meet the actual needs of customers.

Steel ingot heating furnace

6、One-combustion energy saving workshop pictures

The finished products of the Steel ingot heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Steel ingot heating furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Steel ingot heating furnaceis a kind of high quality and low price Steel ingot heating furnace,It is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。

Related recommendation

-

What is a Forging trolley forging furnace? forging furnace specifications, models, and parameters

2025-5-27 -

退火炉

2023-03-25 -

Introduction to Deep well heat treatment quenching furnace, how much is the price of the forging furnace?

2025-5-27 -

What is a Tempering trolley electric furnace? Introduction to the advantages and characteristics of the Trolley electric furnace

2025-5-27 -

防爆天然气台车炉

2023-08-12 -

Introduction to End in side out forging furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Gas trolley furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a Regenerative natural gas tube quenching furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

What is a Industrial well type heating furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

贯通式电阻炉

2023-03-15