Introduction to High temperature roller furnace and forging furnace working principle

High temperature roller furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,widely used in electron, shipping, light industry, automobile, chemical industry and other fields,The structural design is more advanced and reasonable.,it is mainly composed of combustor, ventilation system, recovery of waste heat, ventilation system and recovery of waste heat,Strong adaptability,energy-efficient,Easy to control,energy saving and environmental protection,Easy to maintain,the product looks atmospheric.。The following is to introduce the High temperature roller furnace:

1、Brief introduction of High temperature roller furnace

High temperature roller furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,It has a wide range of uses, including Energy conservation and environmental protection, Improve production efficiency, Metal forging heating, Metal melting and casting and Metal tempering,is a popular High temperature roller furnace。

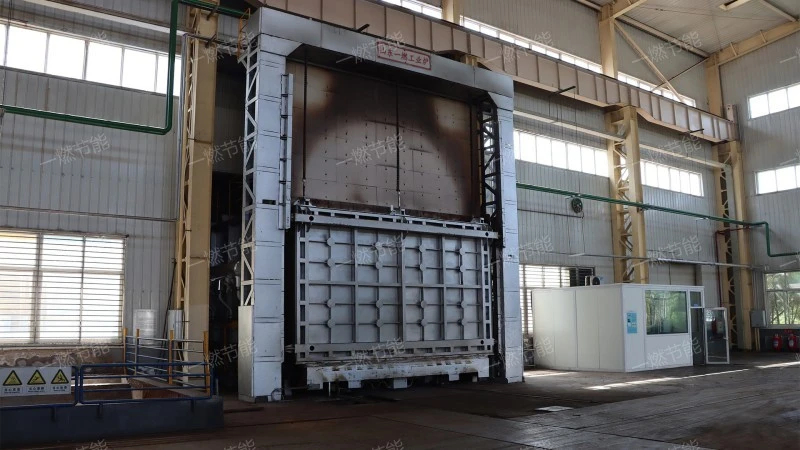

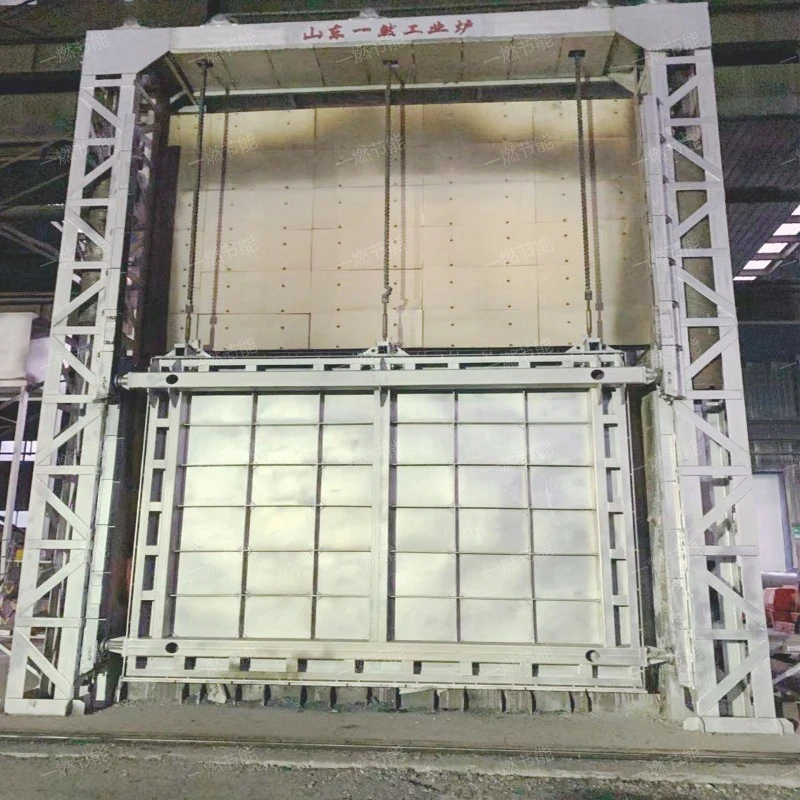

High temperature roller furnace

2、Structural characteristics of High temperature roller furnace

The High temperature roller furnace has the following structure

- Waste heat recovery system

- combustor

- convection chamber

- Waste heat recovery system

- Radiation chamber

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

The heat load of the main place for High temperature roller furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

High temperature roller furnace

3、High temperature roller furnace characteristics

The High temperature roller furnace features are as follows:

- Strong adaptability

- Easy to control

- Easy to maintain

- Efficient heating

- Strong adaptability

The High temperature roller furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The combustion system and ventilation system of the High temperature roller furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The structural design of the High temperature roller furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The High temperature roller furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The High temperature roller furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

High temperature roller furnace

4、High temperature roller furnace HD real picture

High temperature roller furnace specifications and models are complete, and customers can choose at will. High-definition pictures are available for customers' reference. Customers are welcome to visit our factory.。

High temperature roller furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、High temperature roller furnace principle

High temperature roller furnaceat runtime,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.。

High temperature roller furnace

6、High temperature roller furnace function

High temperature roller furnacemultifunctional, with functions such as Forging heating, Forging heating, hardening and tempering, Casting heating and anneal,is a common High temperature roller furnace,the main structure includes furnace chamber, ventilation system, convection chamber, ventilation system, Radiation chamber and so on,High temperature roller furnaceThe overall structural design is simple and novel.,customizable。

High temperature roller furnace

High temperature roller furnaceit has the functions of heat treatment, normalizing, temper, quench and Forging heating,generally, it is composed of ventilation system, furnace chamber, convection chamber, combustor, Radiation chamber and other major components,High temperature roller furnaceSimple structure and advanced technology.,is a High temperature roller furnace。

Related recommendation

-

What is a Hot dip galvanizing heating furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Energy saving and environmentally friendly roller bottom furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Rotary gas trolley furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a Tempering furnace chamber type? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to Roll trolley heating furnace and heating furnace structure principle

2025-5-27 -

Introduction to Rapid quenching heating furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Energy saving tube annealing furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a SCR catalyst denitrification equipment? Introduction to the advantages and characteristics of the SCR flue gas denitrification

2025-5-27 -

Introduction to Forging aluminum rod heating furnace and forging furnace structure principle

2025-5-27 -

What is a Double head annealing heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27