What is a Roller type spheroidization heat treatment furnace? How much is the price of the heating furnace?

Roller type spheroidization heat treatment furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,is a kind of high quality and low price Roller type spheroidization heat treatment furnace,can be customized according to user's needs.。

1、Brief introduction of Roller type spheroidization heat treatment furnace

Roller type spheroidization heat treatment furnaceIt is a forging heating device using gas as fuel.,be of high quality。

Roller type spheroidization heat treatment furnace

2、Introduction of Roller type spheroidization heat treatment furnace characteristics

Roller type spheroidization heat treatment furnace has the following characteristics

- Stable and reliable

- Easy to maintain

- energy saving and environmental protection

- energy saving and environmental protection

- Easy to control

The Roller type spheroidization heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The structural design of the Roller type spheroidization heat treatment furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Roller type spheroidization heat treatment furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

Natural gas is a kind of clean energy, which produces less waste gas and waste smoke after combustion and has little environmental pollution. At the same time, through wall regenerative combustion technology, flue gas waste heat recovery system and other technical means, the Roller type spheroidization heat treatment furnace further improves energy utilization efficiency and reduces energy consumption and emissions.

The combustion system and ventilation system of the Roller type spheroidization heat treatment furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Roller type spheroidization heat treatment furnace

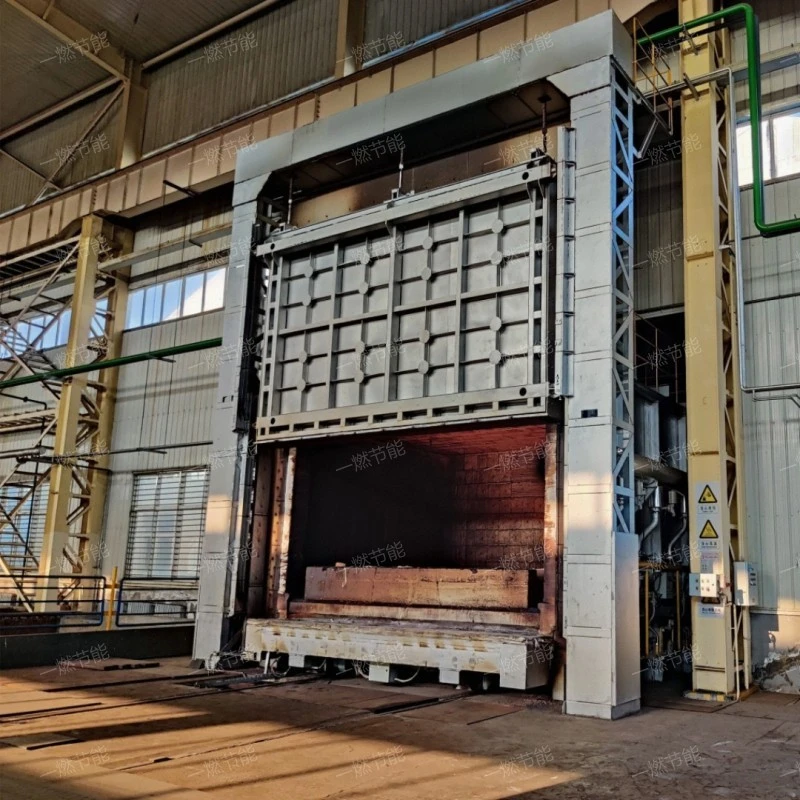

3、Roller type spheroidization heat treatment furnace HD picture

The design of One-combustion energy saving Roller type spheroidization heat treatment furnace is exquisite and elegant. Here are the high-definition pictures of One-combustion energy saving's factory products for our customers' reference. We need to make an appointment to visit the factory in advance for physical inspection.。

Roller type spheroidization heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Roller type spheroidization heat treatment furnace HD real shot

On-site aerial photography of Roller type spheroidization heat treatment furnace。

Roller type spheroidization heat treatment furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd is a popular Roller type spheroidization heat treatment furnace。

5、Introduction of advantages of Roller type spheroidization heat treatment furnace

Roller type spheroidization heat treatment furnaces have the following advantages.

- Rapid temperature rise

- Efficient combustion

- Extend the service life of equipment

- Uniform heating

- Intelligent control

The Roller type spheroidization heat treatment furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

The Roller type spheroidization heat treatment furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Roller type spheroidization heat treatment furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Roller type spheroidization heat treatment furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The Roller type spheroidization heat treatment furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

Roller type spheroidization heat treatment furnace

6、Roller type spheroidization heat treatment furnace quotation

The Roller type spheroidization heat treatment furnace price is introduced as follows:

- technology

- Manufacturer's strength

- product configuration

- brand

- Product technology

The more advanced the technology, the higher the price will be, otherwise the equipment price will be low, and users must pay attention to whether their own technology meets the production requirements when purchasing equipment.

The products manufactured by manufacturers of different scales are also different. Large-scale manufacturers have advanced production technology, the quality of products manufactured is reliable, and large-scale manufacturers have perfect after-sales service, which can provide greater protection for customers and the products manufactured are more cost-effective. Therefore, customers should try to choose large manufacturers to purchase.

The difference in Roller type spheroidization heat treatment furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Different brands of products in the same series have more or less differences in product prices, and different brands of Roller type spheroidization heat treatment furnace have more or less differences in price.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Roller type spheroidization heat treatment furnace

Roller type spheroidization heat treatment furnacemultifunctional, with functions such as anneal, Forging heating, hardening and tempering, heat treatment and Forging heating,Mainly used forMetal heat treatment,Metal forging heating,Metal tempering,Metal heat treatment andMetal melting and casting。

Related recommendation

-

What is a Three-stage gas heating furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Split type deep well furnace and Forging furnace advantages and features

2025-5-27 -

What is a Regenerative roller furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Continuous annealing heat treatment furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Well type copper wire annealing furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Denitrification inside the furnace, SCR denitration system specifications, model parameters

2025-5-27 -

Introduction to Double car mold roasting furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Pit type heat treatment quenching furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to High manganese steel trolley heating furnace and heating furnace working principle

2025-5-27 -

Introduction to Quenching and tempering treatment trolley forging heating furnace and Forging furnace working principle

2025-5-27