What is a Continuous trolley forging furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

Continuous trolley forging furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,multifunctional, with functions such as hardening and tempering, temper, heat treatment, Forging heating and anneal,is designed by One-combustion energy saving with advanced technology。

1、Brief introduction of Continuous trolley forging furnace

Continuous trolley forging furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,is a common Continuous trolley forging furnace。

Continuous trolley forging furnace

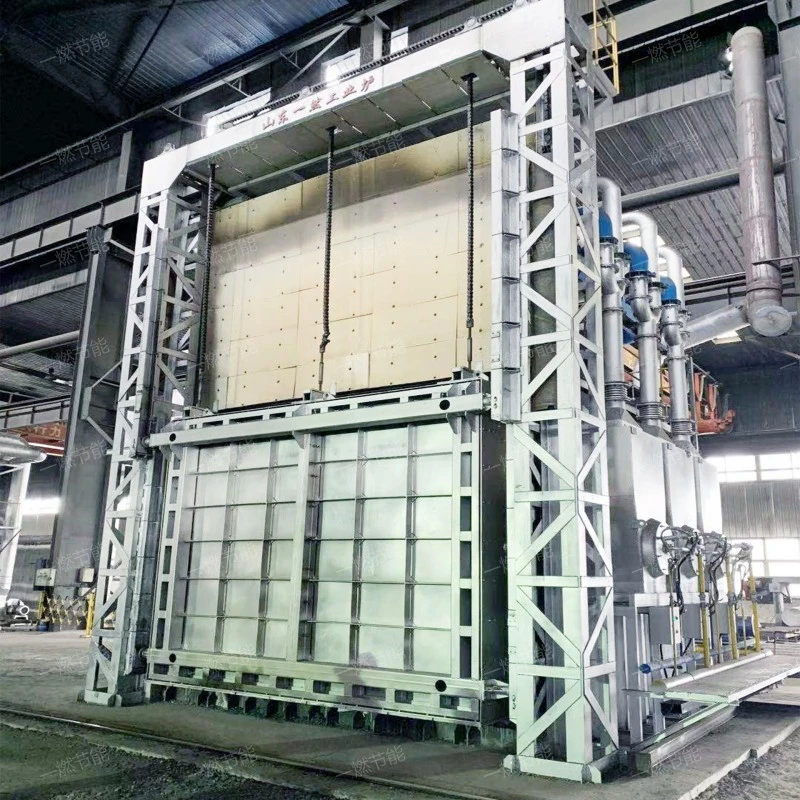

2、Continuous trolley forging furnace HD picture real shot

Continuous trolley forging furnace specifications and models are complete, and customers can choose at will. High-definition pictures are available for customers' reference. Customers are welcome to visit our factory.。

Continuous trolley forging furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Working principle of Continuous trolley forging furnace

Continuous trolley forging furnaceat work,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,is carefully developed by One-combustion energy saving combined with advanced technology。

Continuous trolley forging furnace

4、Continuous trolley forging furnace application

Continuous trolley forging furnaces have the following purposes.

- Improve production efficiency

- Metal tempering

- Improve production efficiency

- Metal forging heating

- Metal tempering

The Continuous trolley forging furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

By properly heating and cooling the metal material, the Continuous trolley forging furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Continuous trolley forging furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Continuous trolley forging furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

By properly heating and cooling the metal material, the Continuous trolley forging furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

Continuous trolley forging furnace

5、Continuous trolley forging furnace price advantage

The Continuous trolley forging furnace price is introduced as follows:

- product costs

- Reasonable sales model

- Self quality

- product configuration

- Product technology

The manufacturing cost has a great influence on the price. There are many cost factors, including the purchase of raw materials and the quality of products. These factors are all cost inputs. One-combustion energy saving has made a strong balance between the cost input and the sales price, so that the quality of our products can be guaranteed and the comprehensive price of products can reach the degree of customer satisfaction.

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

One-combustion energy saving attaches great importance to the quality of products, which can be reflected in the manufacturing process of Continuous trolley forging furnace and the handling of details. Therefore, there is also a close relationship between quality and price. The price of high-quality products will naturally be high, and vice versa.

Products of the same style, different configurations, the product price is definitely different, therefore, the Continuous trolley forging furnace price is affected by the configuration, and the price varies.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

Continuous trolley forging furnace

6、One-combustion energy saving company discount

Continuous trolley forging furnace is a new type of forging furnace introduced by One-combustion energy saving manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for material and other industries. Now consult One-combustion energy savingContinuous trolley forging furnace, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Continuous trolley forging furnaceit is widely used in machinery, heat treatment, electron, surface treatment, Household necessities and other industries,in the course of work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Related recommendation

-

Introduction to Large scale through forging furnace and Forging furnace structure principle

2025-5-27 -

What is a Steel chain heating furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Plate chain continuous heat treatment furnace, how much is the price of the heating furnace?

2025-5-27 -

What is a Casting forging heating furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Multi chamber quenching furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to High temperature industrial heating furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a High temperature roller bottom furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

What is a Well type quenching heating furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

What is a Resistance heating and tempering furnace? Trolley resistance furnace specifications, models, and parameters

2025-5-27 -

What is a Top fired forging box type heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27