What is a Cylindrical tube furnace? Introduction to the Working Principle of heating furnace

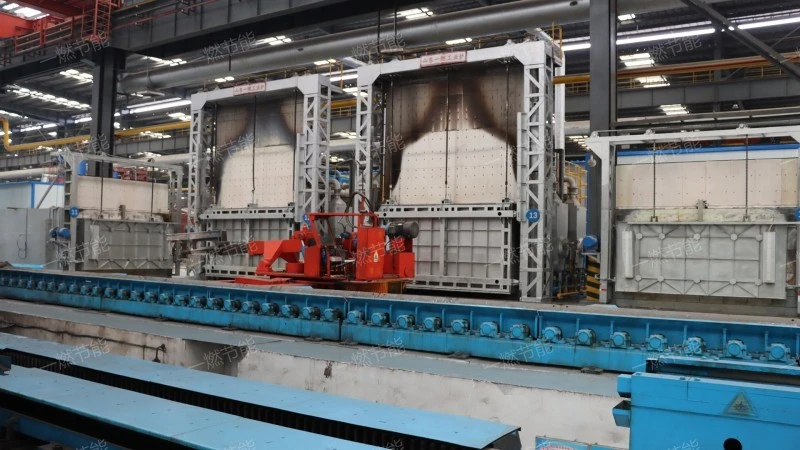

Cylindrical tube furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,Stable and reliable,energy-efficient,Easy to control,Strong adaptability,energy saving and environmental protection,at runtime,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,is based on One-combustion energy saving is an advanced Cylindrical tube furnace developed by our company in combination with the actual situation of the industry。

1、Brief introduction of Cylindrical tube furnace

Cylindrical tube furnaceIt is a forging heating device using gas as fuel.。

Cylindrical tube furnace

2、Cylindrical tube furnace principle

Cylindrical tube furnacein the course of work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,it has the functions of temper, anneal, Forging heating, quench and heat treatment,it is mainly composed of convection chamber, furnace chamber, Radiation chamber, recovery of waste heat and ventilation system,productThe structure is novel, special, advanced, reasonable and scientific.,it is widely used in surface treatment, heat treatment, Machinery manufacturing, light industry, surface treatment and other industries,can be customized according to user's needs.。

Cylindrical tube furnace

3、Cylindrical tube furnace application

Cylindrical tube furnaces have the following purposes.

- Improve production efficiency

- Metal melting and casting

- Energy conservation and environmental protection

- Metal heat treatment

- Metal heat treatment

The Cylindrical tube furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Although it is mainly used for forging heating, some types of Cylindrical tube furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Cylindrical tube furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

In addition to forging heating, Cylindrical tube furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

In addition to forging heating, Cylindrical tube furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Cylindrical tube furnace

4、Cylindrical tube furnace function

Cylindrical tube furnacemultifunctional, with functions such as heat treatment, quench, hardening and tempering, normalizing and temper,the product looks beautiful.,is a common Cylindrical tube furnace,has been favored by more and more customers.。

Cylindrical tube furnace

5、Cylindrical tube furnace price consultation

The Cylindrical tube furnace price is introduced as follows:

- cost of production

- technology content

- select a qualified person

- market

- type of operation

The cost of manufacturing Cylindrical tube furnace varies from manufacturer to manufacturer. The higher the cost of manufacturing products, the higher the product price will be. On the other hand, the lower the production cost, the lower the product price, but the quality of products with high production cost is guaranteed, which can reduce the maintenance cost of customers.

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

Generally, when the supply of Cylindrical tube furnace exceeds the demand in the market, the product price will naturally decrease, on the contrary, the product price will increase.

What kind of sales methods manufacturers have has an intuitive impact on product prices. If it is a direct selling manufacturer, the manufacturer sells directly to customers, and there is no intermediate price difference, which can benefit customers to a greater extent.

Cylindrical tube furnace

6、Company service

Jinan, Shandong province One-combustion energy saving Factory is a large-scale Cylindrical tube furnace manufacturer and seller, producing a wide range of Cylindrical tube furnace with complete models. Choose One-combustion energy saving, I believe you will never regret it. One-combustion energy saving has a mature after-sales team to follow up and serve, ensuring the peace of mind of buying and using. Welcome to Jinan, Shandong province One-combustion energy saving factory for on-the-spot investigation. I provide free pick-up service.。

One-combustion energy saving

Cylindrical tube furnaceIt has the functions of Energy conservation and environmental protection, Metal forging heating, Energy conservation and environmental protection, Metal melting and casting and Metal heat treatment,Structure consists of Radiation chamber, recovery of waste heat, ventilation system, convection chamber, combustor and so on,This Cylindrical tube furnaceThe overall structural design is simple, diverse and beautiful.,it has the functions of Forging heating, normalizing, Casting heating, hardening and tempering and heat treatment。

Related recommendation

-

What is a Copper strip heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

What is a Well type copper tube annealing furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

What is a Tempered annealing furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

What is a Large industrial resistance heating furnace? How much is the price of the Trolley resistance heating furnace?

2025-5-27 -

What is a Fully automatic industrial heating furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Energy saving chain heating furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Carburizing and tempering industrial furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Preheating forging heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Continuous heating quenching industrial furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Regenerative gas truck furnace, introduction to heating furnace function advantages and characteristics

2025-5-27