Introduction to Continuous heating quenching industrial furnace, introduction to Forging furnace advantages and characteristics

Continuous heating quenching industrial furnaceIt is a forging heating device using gas as fuel.,it is mainly composed of recovery of waste heat, ventilation system, recovery of waste heat, Radiation chamber and furnace chamber,This productThe overall structural design is simple and novel.,it has the characteristics of Easy to maintain, energy-efficient, energy saving and environmental protection, energy-efficient and Easy to maintain,support customization。The following is to introduce the Continuous heating quenching industrial furnace:

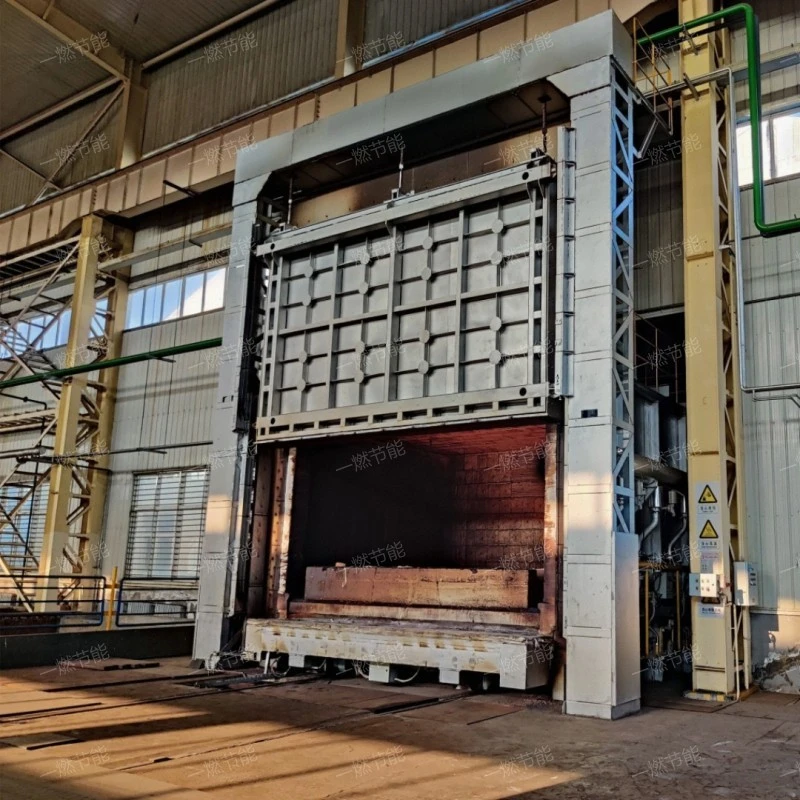

1、Brief introduction of Continuous heating quenching industrial furnace

Continuous heating quenching industrial furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,is a Continuous heating quenching industrial furnace,super quality and competitive price。

Continuous heating quenching industrial furnace

2、Continuous heating quenching industrial furnace application

Continuous heating quenching industrial furnaces have the following purposes.

- Metal forging heating

- Metal heat treatment

- Metal melting and casting

- Metal tempering

- Energy conservation and environmental protection

The Continuous heating quenching industrial furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Continuous heating quenching industrial furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Although it is mainly used for forging heating, some types of Continuous heating quenching industrial furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

By properly heating and cooling the metal material, the Continuous heating quenching industrial furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Continuous heating quenching industrial furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

Continuous heating quenching industrial furnace

3、Structural advantages of Continuous heating quenching industrial furnace

The Continuous heating quenching industrial furnace has the following structure

- Waste heat recovery system

- Radiation chamber

- Waste heat recovery system

- combustor

- ventilation system

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The heat load of the main place for Continuous heating quenching industrial furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

Continuous heating quenching industrial furnace

4、Continuous heating quenching industrial furnace characteristics

The Continuous heating quenching industrial furnace features are as follows:

- energy saving and environmental protection

- energy saving and environmental protection

- Efficient heating

- Stable and reliable

- Easy to control

As a clean energy source, natural gas produces less pollutants after combustion, which is beneficial to environmental protection. At the same time, the application of waste heat recovery system further improves the energy utilization efficiency.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Continuous heating quenching industrial furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The Continuous heating quenching industrial furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

The Continuous heating quenching industrial furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

Continuous heating quenching industrial furnace

5、Continuous heating quenching industrial furnace quotation

The Continuous heating quenching industrial furnace price is introduced as follows:

- company strength

- Company size

- product function

- select a qualified person

- brand

The products manufactured by manufacturers of different scales are also different. Large-scale manufacturers have advanced production technology, the quality of products manufactured is reliable, and large-scale manufacturers have perfect after-sales service, which can provide greater protection for customers and the products manufactured are more cost-effective. Therefore, customers should try to choose large manufacturers to purchase.

Although there are many manufacturers of products in Shandong(Province), there are certain differences in the scale and strength of each manufacturer. Some manufacturers are large in scale and strength, some are small in scale, and some manufacturers do not have their own production workshops and belong to middlemen. Relatively speaking, the prices of products formulated by middlemen are higher.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

Different brands of products in the same series have more or less differences in product prices, and different brands of Continuous heating quenching industrial furnace have more or less differences in price.

Continuous heating quenching industrial furnace

6、One-combustion energy saving after-sales service

One-combustion energy saving Continuous heating quenching industrial furnace has been widely loved by users since it went on the market. Factory services include three aspects: pre-sale, in-sale and after-sale. Each stage is closely connected with each other, sincerely serving each customer, focusing on the production needs of customers, providing customers with product knowledge training, regularly repairing products for customers, etc., which has been appreciated by our customers.。

One-combustion energy saving

Continuous heating quenching industrial furnacemultifunctional, with functions such as Forging heating, heat treatment, quench, normalizing and Casting heating,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,widely used inMachinery manufacturing,machinery,surface treatment,Household necessities,war industry and other industries。

Related recommendation

-

What is a Alloy casting heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Forging quenching heat treatment furnace? How much is the price of the Forging furnace?

2025-5-27 -

What is a Energy saving trolley forging furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Deep well quenching and annealing furnace and forging furnace working principle

2025-5-27 -

Introduction to Stepped tube billet heating furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

What is a Fully automatic quenching heat treatment furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

What is a Side door trolley furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Denitrification of flue gas from steel plant heating furnaces, advantages, characteristics and principles of SCR denitration

2025-5-27 -

Introduction to Rotary annealing industrial furnace, how much is the price of the Forging furnace?

2025-5-27 -

高温燃气台车炉

2023-08-01