Introduction to Low temperature quenching and tempering heat treatment furnace, Forging furnace specifications, model parameters

Low temperature quenching and tempering heat treatment furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.。The following is to introduce the Low temperature quenching and tempering heat treatment furnace:

1、Brief introduction of Low temperature quenching and tempering heat treatment furnace

Low temperature quenching and tempering heat treatment furnaceIt is a forging heating device using gas as fuel.,is a Low temperature quenching and tempering heat treatment furnace,it is widely used inpharmacy,light industry,electron,building materials,surface treatment and other industries,be loved by our customers.。

Low temperature quenching and tempering heat treatment furnace

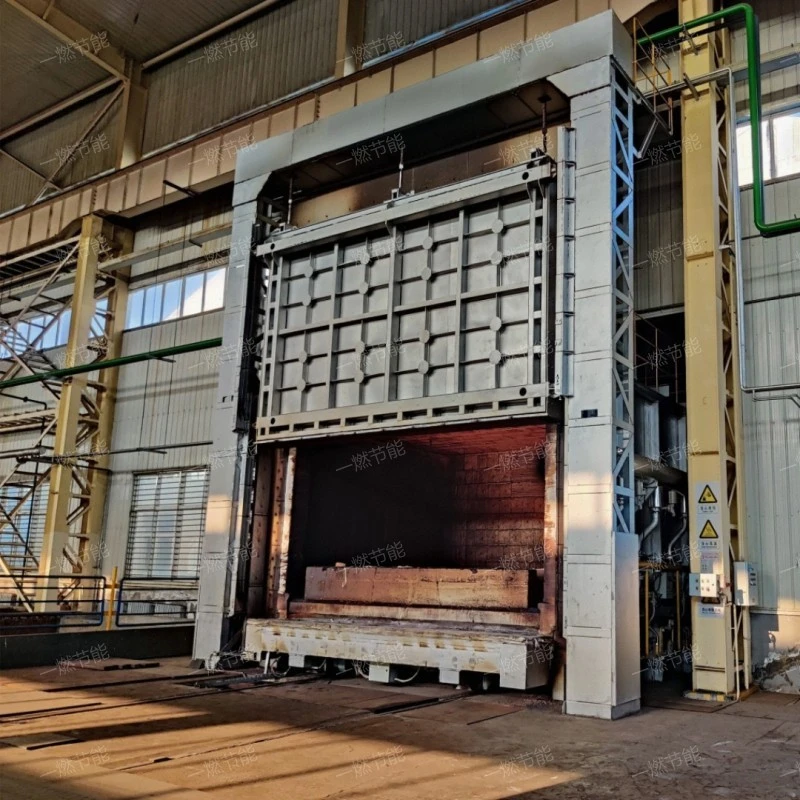

2、Low temperature quenching and tempering heat treatment furnace HD real shot

The omni-directional high-definition real shot of the Low temperature quenching and tempering heat treatment furnace is shown as follows to meet the purchase needs of our customers.。

Low temperature quenching and tempering heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Low temperature quenching and tempering heat treatment furnace structure

The Low temperature quenching and tempering heat treatment furnace structure is introduced as follows:

- Waste heat recovery system

- ventilation system

- furnace chamber

- Radiation chamber

- furnace chamber

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

A space for holding metallic materials for heating.

The heat load of the main place for Low temperature quenching and tempering heat treatment furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

Low temperature quenching and tempering heat treatment furnace

4、On-site real shot of Low temperature quenching and tempering heat treatment furnace

Low temperature quenching and tempering heat treatment furnace specifications and models are complete, and customers can choose at will. High-definition pictures are available for customers' reference. Customers are welcome to visit our factory.。

Low temperature quenching and tempering heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、How much is the Low temperature quenching and tempering heat treatment furnace?

The Low temperature quenching and tempering heat treatment furnace price is introduced as follows:

- Parameter size

- Brand strength

- quality factor

- product costs

- Model specification

The same type of products, with different specifications, models and sizes, have different costs, so the quotations to customers naturally vary. Generally speaking, the larger the model, the higher the price, and the smaller the model, the lower the price.

At present, there are various brands of Low temperature quenching and tempering heat treatment furnace in Jinan, Shandong province. The performance, quality and after-sales of products under different brands are different, and the prices of Low temperature quenching and tempering heat treatment furnace are different.

Usually, the price of good quality products will be higher, because the product has higher technical content and more costs in raw materials and labor, but the performance of such products is higher and the profits will be higher. On the contrary, the price of ordinary quality products will be relatively lower, but the benefits will be correspondingly poor.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the Low temperature quenching and tempering heat treatment furnace.

One-combustion energy saving is a large professional Low temperature quenching and tempering heat treatment furnaceManufacturer and seller, the Low temperature quenching and tempering heat treatment furnace of various specifications and models manufactured are affordable, reliable in quality, good in performance and perfect after-sales, which is a good choice for everyone to buy Low temperature quenching and tempering heat treatment furnace.

Low temperature quenching and tempering heat treatment furnace

6、One-combustion energy saving company discount

Low temperature quenching and tempering heat treatment furnace is a new type of Forging furnace introduced by Shandong yiran energy-saving environment protection co., ltd manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for machinery and other industries. Now consult One-combustion energy savingLow temperature quenching and tempering heat treatment furnace, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Low temperature quenching and tempering heat treatment furnaceStructure consists of ventilation system, combustor, Radiation chamber, furnace chamber, recovery of waste heat and so on,Low temperature quenching and tempering heat treatment furnaceSimple structure and advanced technology.,multifunctional, with functions such as anneal, hardening and tempering, temper, hardening and tempering and temper,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

Related recommendation

-

What is a Round tube heat treatment furnace? How much is the price of the Forging furnace?

2025-5-27 -

Introduction to Quenching and tempering treatment trolley forging heating furnace and Forging furnace working principle

2025-5-27 -

Introduction to High temperature chain heat treatment furnace and heating furnace advantages and features

2025-5-27 -

What is a Automated deep well furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Continuous quenching heat treatment furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

What is a High temperature SCR flue gas denitrification? Introduction to the principle of SCR flue gas denitrification structure

2025-5-27 -

Introduction to Fully automatic deep well furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Rotary heat treatment heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Rapid quenching heating furnace, how much is the price of the heating furnace?

2025-5-27 -

What is a Fully automatic well quenching furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27