What is a High temperature SCR flue gas denitrification? Introduction to the principle of SCR flue gas denitrification structure

High temperature SCR flue gas denitrificationthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,is a High temperature SCR flue gas denitrification,Widely used in environmental protection, Improve product quality, Flue gas denitrification, environmental protection and Promote sustainable development,it has the functions of Improve energy efficiency, Improve working conditions, environmental protection, Improve energy efficiency and Promote sustainable development,the product looks beautiful.。The following is to introduce the High temperature SCR flue gas denitrification:

1、Brief introduction of High temperature SCR flue gas denitrification

High temperature SCR flue gas denitrificationdelective catalytic reduction technology is an efficient flue gas denitrification technology.,at work,Ammonia gas or other suitable reducing agent (such as urea aqueous solution) is sprayed into the flue gas upstream of the catalyst at high temperature. Under the action of catalyst, the reducing agent selectively reacts with nitrogen oxides (NOx) in flue gas to generate pollution-free nitrogen and water vapor. Because NH3 is selective, it only reacts with NOx and basically does not react with O2, so this technology is called selective catalytic reduction denitrification.。

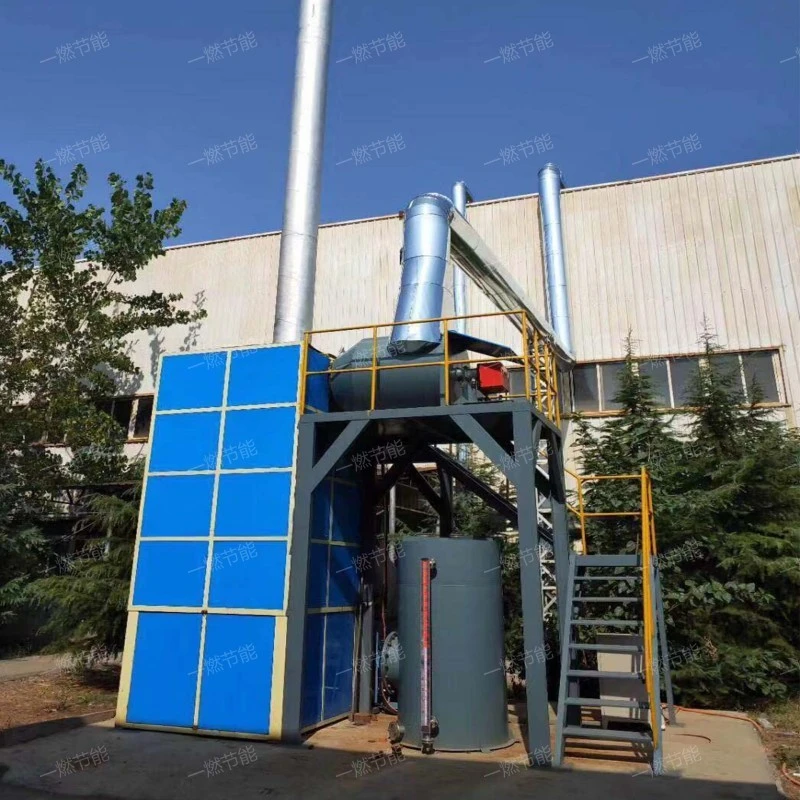

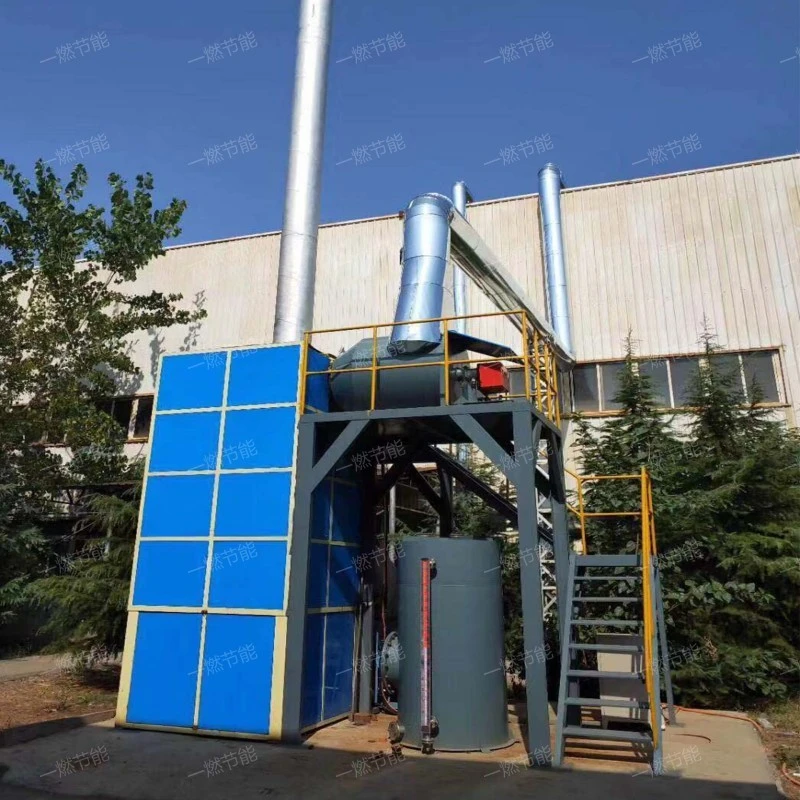

High temperature SCR flue gas denitrification

2、High temperature SCR flue gas denitrification function

High temperature SCR flue gas denitrificationmultifunctional, with functions such as Improve working conditions, environmental protection, Improve working conditions, Improve energy efficiency and Promote sustainable development,that is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,the main structure includes Catalyst supply system, control system, Catalyst reactor, Temperature control and monitoring system and Flue gas mixing and distribution system,This High temperature SCR flue gas denitrificationThe structural design is more advanced and reasonable.,it has been widely used in metallurgy, building materials, Gas power plant, iron and steel plant, cement plant and other industries,features include High denitration efficiency, Stable operation, Promote sustainable development, Stable operation and energy saving and environmental protection。

High temperature SCR flue gas denitrification

3、High temperature SCR flue gas denitrification characteristics

The High temperature SCR flue gas denitrification features are as follows:

- high efficiency

- Mature technology

- selectivity

- energy saving and environmental protection

- Strong adaptability

Gate technology can effectively remove NOx from flue gas, and the denitrification efficiency can usually reach more than 90%.

After years of development and application, High temperature SCR flue gas denitrification technology is very mature and has a wide application prospect.

Under the action of catalyst, the reducing agent mainly reacts with NOx selectively, but less with other components (such as oxygen) in flue gas, thus reducing unnecessary consumption.

This technology can effectively reduce NOx emission in flue gas, reduce environmental pollution, and at the same time, it has stable operation and low energy consumption, which meets the requirements of energy saving and environmental protection.

High temperature SCR flue gas denitrification technology can meet the needs of flue gas denitrification under different working conditions and has a wide range of applications.

High temperature SCR flue gas denitrification

4、High temperature SCR flue gas denitrification use

High temperature SCR flue gas denitrificationWidely used inMeet the requirements of environmental protection,Improve product quality,Flue gas denitrification,Meet the requirements of environmental protection,Promote sustainable development and so on,The overall structural design is relatively simple,it mainly includes Catalyst supply system, control system, Flue gas mixing and distribution system, Temperature control and monitoring system and Catalyst reactor。

High temperature SCR flue gas denitrification

5、How much is the High temperature SCR flue gas denitrification?

The High temperature SCR flue gas denitrification price is introduced as follows:

- marketing channel

- region

- Quality advantages and disadvantages

- raw material

- product model

If there is no middleman to earn the difference, then the High temperature SCR flue gas denitrification price will naturally decrease. One-combustion energy saving adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

One-combustion energy savingJinan, Shandong province, the transportation is convenient, and the corresponding cost of transporting High temperature SCR flue gas denitrification is low, which reduces the cost of selling High temperature SCR flue gas denitrification by manufacturers, and the price will also decrease.

The quality of the High temperature SCR flue gas denitrification is the key factor that affects its price. The manufacturer of high-quality products has high cost in production and high product performance, which can bring higher economic benefits to customers. Because the manufacturer of high-quality products has high production investment, the manufacturer is on the high side when positioning the High temperature SCR flue gas denitrification price.

The raw materials used by different manufacturers will also be different. The better the raw materials, the better the quality and performance of the products and the higher the price. On the contrary, the products made of ordinary materials have low production costs and much lower prices.

There are many specifications and models of High temperature SCR flue gas denitrification in the market now. Under normal circumstances, the price of large-sized High temperature SCR flue gas denitrification is definitely higher than that of small-sized High temperature SCR flue gas denitrification.

High temperature SCR flue gas denitrification

6、company introduction

One-combustion energy saving is a professional and large-scale High temperature SCR flue gas denitrification manufacturer, which has many years of production and operation, complete production facilities, skilled staff and high production capacity and product quality. It is a High temperature SCR flue gas denitrification manufacturer trusted by consumers at present.。

One-combustion energy saving

High temperature SCR flue gas denitrificationit has the functions of environmental protection, Promote sustainable development, Improve energy efficiency, Improve working conditions and environmental protection,is a High temperature SCR flue gas denitrification,multifunctional, with functions such as Promote sustainable development, Improve energy efficiency, Improve working conditions, environmental protection and Improve energy efficiency。

Related recommendation

-

Introduction to SCR flue gas catalytic denitrification system and SCR denitration system advantages and features

2025-5-27 -

Introduction to Medium sized trolley heating furnace and heating furnace working principle

2025-5-27 -

What is a Pressure vessel trolley furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27 -

Introduction to Heat treatment well furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to resistance heating furnace and Trolley electric heating furnace structure principle

2025-5-27 -

Introduction to Bright industrial resistance heating furnace, how much is the price of the Trolley resistance heating furnace?

2025-5-27 -

What is a Isothermal heat treatment furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Casting trolley furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to Steel strip heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to Continuous roller quenching heat treatment furnace, forging furnace advantages, characteristics and principles

2025-5-27