Introduction to Continuous isothermal quenching heating furnace, Forging furnace specifications, model parameters

Continuous isothermal quenching heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.。The following is to introduce the Continuous isothermal quenching heating furnace:

1、Brief introduction of Continuous isothermal quenching heating furnace

Continuous isothermal quenching heating furnaceIt is a forging heating device using gas as fuel.,can be customized according to user's needs.。

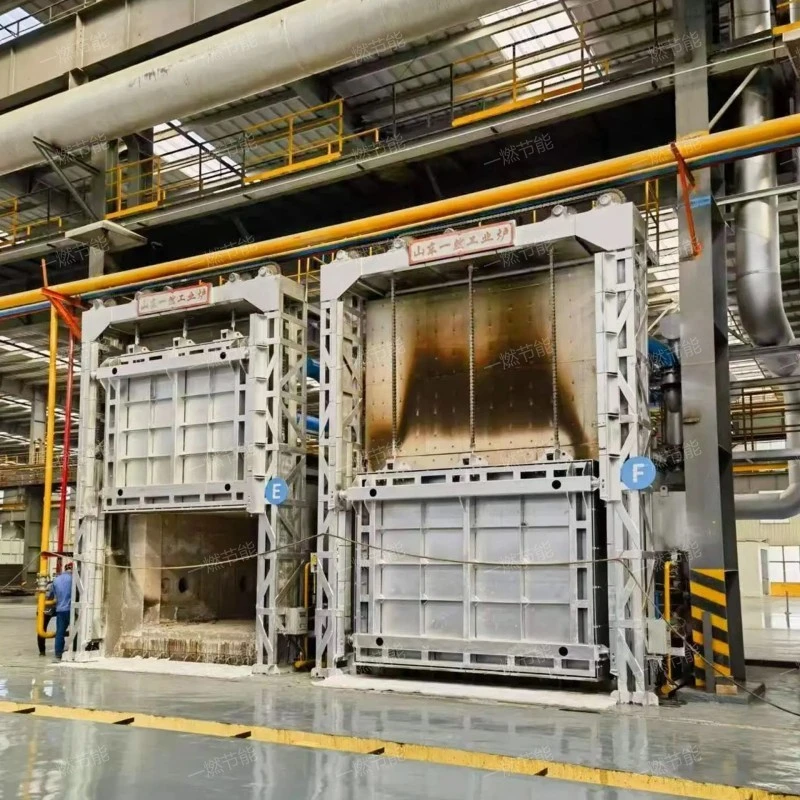

Continuous isothermal quenching heating furnace

2、Continuous isothermal quenching heating furnace advantage

Continuous isothermal quenching heating furnaces have the following advantages.

- Wide application range

- Extend the service life of equipment

- clean energy

- Intelligent control

- Efficient combustion

The Continuous isothermal quenching heating furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

The Continuous isothermal quenching heating furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

The Continuous isothermal quenching heating furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The Continuous isothermal quenching heating furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

Continuous isothermal quenching heating furnace

3、Continuous isothermal quenching heating furnace function

Continuous isothermal quenching heating furnaceit has the functions of hardening and tempering, Forging heating, normalizing, Casting heating and heat treatment。

Continuous isothermal quenching heating furnace

4、Advantages of Continuous isothermal quenching heating furnace principle

Continuous isothermal quenching heating furnaceat work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,the product looks atmospheric.,The overall structural design is relatively simple,it mainly includes Radiation chamber, ventilation system, ventilation system, furnace chamber and convection chamber,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,Mainly used forImprove production efficiency,Metal heat treatment,Metal melting and casting,Improve production efficiency andEnergy conservation and environmental protection。

Continuous isothermal quenching heating furnace

5、How much is the Continuous isothermal quenching heating furnace?

The Continuous isothermal quenching heating furnace price is introduced as follows:

- After-sales service level

- geographical position

- market quotation

- product configuration

- region

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Continuous isothermal quenching heating furnace price and service can meet the actual needs of customers.

Different provinces and regions have different consumption levels, different market positioning and different prices.

In order to build their own brands, some manufacturers deliberately reduce the price of Continuous isothermal quenching heating furnace. The price of competitors will affect the pricing of equipment more or less, and the price may be lower.

Usually, the quotation of Continuous isothermal quenching heating furnace changes with its configuration, but the quotation is different according to the different needs of customers and different product configurations.

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

Continuous isothermal quenching heating furnace

6、Brief introduction of One-combustion energy saving

One-combustion energy saving, as one of the professional and powerful Continuous isothermal quenching heating furnace manufacturers in Shandong(Province), produces Continuous isothermal quenching heating furnace with reliable quality, affordable price and perfect after-sales, which have been successfully practiced in many processing plants at home and abroad.。

One-combustion energy saving

Continuous isothermal quenching heating furnaceit is widely used in electron, pharmacy, Household necessities, light industry and material,It is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,it has the characteristics of Strong adaptability, energy-efficient, Easy to control, Easy to maintain and Easy to maintain。

Related recommendation

-

Introduction to Pit type heating furnace and heating furnace working principle

2025-5-27 -

调质台车加热炉

2023-08-03 -

Introduction to Metal heat treatment trolley heating furnace and heating furnace structure principle

2025-5-27 -

Introduction to SCR catalytic oxidation denitrification system, advantages, characteristics and principles of SCR denitration system

2025-5-27 -

Introduction to Trolley type high-temperature furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Gas box furnace? Introduction to the advantages and characteristics of the Forging furnace

2025-5-27 -

Introduction to Trolley roaster, introduction to Forging furnace advantages and characteristics

2025-5-27 -

台车式调质炉

2023-06-18 -

What is a Explosion proof well furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Low temperature catalytic denitrification equipment, SCR flue gas denitrification specifications, model parameters

2025-5-27