What is a Bright Annealing Industrial Furnace? Introduction to the advantages and characteristics of the forging furnace

Bright Annealing Industrial FurnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,Widely used inMetal heat treatment,Metal tempering,Metal melting and casting,Energy conservation and environmental protection,Metal forging heating and so on,the product looks beautiful.,at the start of the operation,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,it is an ideal choice for customers to buy Bright Annealing Industrial Furnace。The following is to introduce the Bright Annealing Industrial Furnace:

1、Brief introduction of Bright Annealing Industrial Furnace

Bright Annealing Industrial FurnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,it has the functions of normalizing, quench, Casting heating, normalizing and hardening and tempering,It can be used for Metal heat treatment, Metal melting and casting, Metal tempering, Energy conservation and environmental protection, Improve production efficiency, Metal forging heating and so on。

Bright Annealing Industrial Furnace

2、Video analysis of Bright Annealing Industrial Furnace

The following is the live video of Bright Annealing Industrial Furnace designed and produced by One-combustion energy saving for users, from which we can see the The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Natural gas is used as a heat source, resulting in less waste gas and smoke after combustion, and less pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials. of Bright Annealing Industrial Furnace.。

Bright Annealing Industrial Furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd the advantage is Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、Usually equipped with intelligent control system, it can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.。

3、Bright Annealing Industrial Furnace principle

Bright Annealing Industrial Furnacethe principle is simple.Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,the main structure includes Radiation chamber, convection chamber, furnace chamber, ventilation system, Radiation chamber and so on,Bright Annealing Industrial FurnaceSimple structure and reliable operation.。

Bright Annealing Industrial Furnace

4、Bright Annealing Industrial Furnace characteristics

The Bright Annealing Industrial Furnace features are as follows:

- Efficient heating

- energy saving and environmental protection

- Strong adaptability

- Efficient heating

- Strong adaptability

The Bright Annealing Industrial Furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

As a clean energy source, natural gas produces less pollutants after combustion, which is beneficial to environmental protection. At the same time, the application of waste heat recovery system further improves the energy utilization efficiency.

The Bright Annealing Industrial Furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

The Bright Annealing Industrial Furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Bright Annealing Industrial Furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

Bright Annealing Industrial Furnace

5、Bright Annealing Industrial Furnace price concessions

The Bright Annealing Industrial Furnace price is introduced as follows:

- product quality

- Sales model

- Product configuration difference

- Product technology

- raw material

Quality generally refers to the quality of the product. The better the quality, the higher the quality of the product. Because the quality is directly proportional to the cost of the product, the price of the Bright Annealing Industrial Furnace will vary greatly. One-combustion energy saving attaches great importance to the quality of products, and the formulation of prices is also reasonable.

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

The difference in Bright Annealing Industrial Furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

Bright Annealing Industrial Furnace

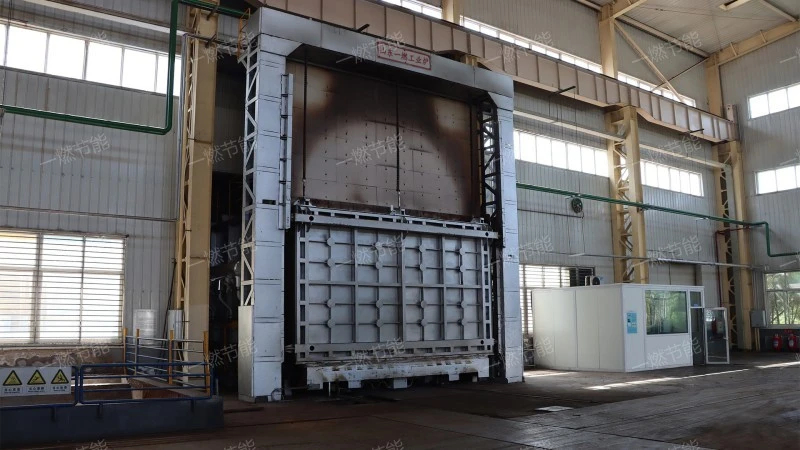

6、One-combustion energy saving workshop real shot

The finished products of the Bright Annealing Industrial Furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

One-combustion energy saving

The finished products of the Bright Annealing Industrial Furnace factory are actually photographed, and all kinds of specifications and models are photographed in all directions. The design is exquisite and the quality is reliable. Don't forget to make an appointment to visit the factory by phone.。

Bright Annealing Industrial Furnaceit has the functions of anneal, temper, Forging heating, heat treatment and quench,is a Bright Annealing Industrial Furnace,it mainly includes ventilation system, ventilation system, recovery of waste heat, ventilation system and combustor。

Related recommendation

-

What is a Well type annealing furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Trolley mold heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Multi functional step heating furnace? heating furnace specifications, models, and parameters

2025-5-27 -

What is a Multi tube roasting furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

Introduction to Decarbonization annealing heat treatment furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

What is a Foundry denitration system? SCR denitration system specifications, models, and parameters

2025-5-27 -

What is a Automatic temperature control step advance and retreat furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Large stainless steel annealing electric heating furnace? Introduction to the Working Principle of Trolley electric furnace

2025-5-27 -

What is a Deep well roasting furnace? Introduction to the Working Principle of Forging furnace

2025-5-27 -

Introduction to Energy saving tube quenching furnace, introduction to Forging furnace advantages and characteristics

2025-5-27