Introduction to Continuous forging heating furnace, Forging furnace advantages, characteristics and principles

Continuous forging heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,multifunctional, with functions such as Forging heating, anneal, Casting heating, Forging heating and hardening and tempering,it is an ideal choice for customers to buy Continuous forging heating furnace。

1、Brief introduction of Continuous forging heating furnace

Continuous forging heating furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it has the characteristics of energy-efficient, Easy to maintain, Strong adaptability, Easy to control and energy-efficient。

Continuous forging heating furnace

2、Continuous forging heating furnace application

Continuous forging heating furnaces have the following purposes.

- Metal melting and casting

- Metal forging heating

- Energy conservation and environmental protection

- Metal heat treatment

- Metal tempering

Although it is mainly used for forging heating, some types of Continuous forging heating furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

The Continuous forging heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Continuous forging heating furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

In addition to forging heating, Continuous forging heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Continuous forging heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

Continuous forging heating furnace

3、Advantages of Continuous forging heating furnace principle

Continuous forging heating furnaceat runtime,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,be loved by our customers.。

Continuous forging heating furnace

4、Introduction of Continuous forging heating furnace characteristics

Continuous forging heating furnace has the following characteristics

- Easy to control

- Easy to control

- Strong adaptability

- Efficient heating

- Stable and reliable

The combustion system and ventilation system of the Continuous forging heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The combustion system and ventilation system of the Continuous forging heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Continuous forging heating furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The Continuous forging heating furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Continuous forging heating furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Continuous forging heating furnace

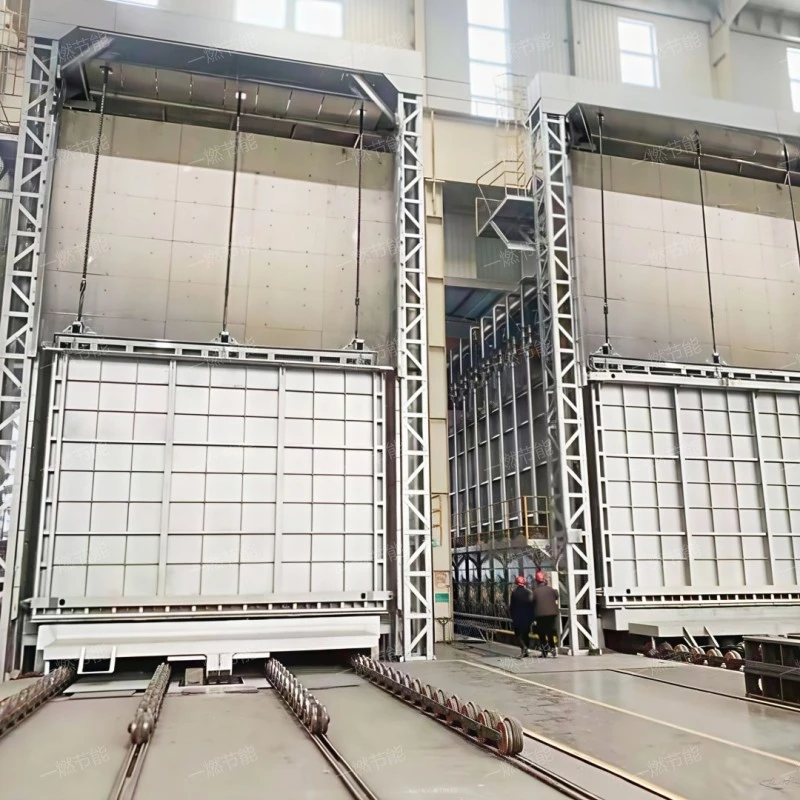

5、Continuous forging heating furnace real shot picture

High-definition pictures of various types of Continuous forging heating furnace are displayed for customers who are about to buy. Please submit a telephone appointment for physical inspection.。

Continuous forging heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、Continuous forging heating furnace price concessions

The Continuous forging heating furnace price is introduced as follows:

- Less intermediate links

- model

- Manufacturer scale

- deploy

- product function

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

The prices of products with different specifications and models will definitely be different. Generally speaking, the larger the specifications and models, the higher the prices will be. Because the raw materials and time consumed in the manufacturing process of large-sized products are more, the prices are much higher than those of small-sized products.

Although there are many manufacturers of products in Jinan, Shandong province, there are certain differences in the scale and strength of each manufacturer. Some manufacturers are large in scale and strength, some are small in scale, and some manufacturers do not have their own production workshops and belong to middlemen. Relatively speaking, the prices of products formulated by middlemen are higher.

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. One-combustion energy saving pays special attention to the hardware configuration of products, so One-combustion energy saving Continuous forging heating furnace has a higher cost performance.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Continuous forging heating furnace

Continuous forging heating furnaceit has the functions of heat treatment, normalizing, temper, quench and anneal,Mainly used forMetal melting and casting,Metal forging heating,Improve production efficiency,Metal melting and casting andMetal heat treatment。

Related recommendation

-

What is a Double door annealing and heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

Introduction to Industrial heating furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to Automatic loading and unloading heating furnace, how much is the price of the heating furnace?

2025-5-27 -

What is a Chain plate automatic heating furnace? Introduction to the advantages and characteristics of forging furnace functions

2025-5-27 -

Introduction of Preheating forging heating furnace

2025-6-18 -

Introduction to Quenching heat treatment electric heating furnace, advantages, characteristics and principles of Trolley electric furnace

2025-5-27 -

Introduction to Isothermal quenching heat treatment industrial furnace and Forging furnace structure principle

2025-5-27 -

台车式模壳加热炉

2023-07-25 -

Introduction to Adjustable resistance furnace, Trolley resistance heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Energy saving and environmentally friendly chain annealing furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

2025-5-27