What is a Forged heating furnace flue gas denitrification equipment? Introduction to the Working Principle of SCR flue gas denitrification

Forged heating furnace flue gas denitrification equipmentdelective catalytic reduction technology is an efficient flue gas denitrification technology.。

1、Brief introduction of Forged heating furnace flue gas denitrification equipment

Forged heating furnace flue gas denitrification equipmentis an efficient, stable and environment-friendly flue gas denitrification technology.,generally, it is composed of Catalyst supply system, control system, Catalyst reactor, Temperature control and monitoring system, Flue gas mixing and distribution system and other major components。

Forged heating furnace flue gas denitrification equipment

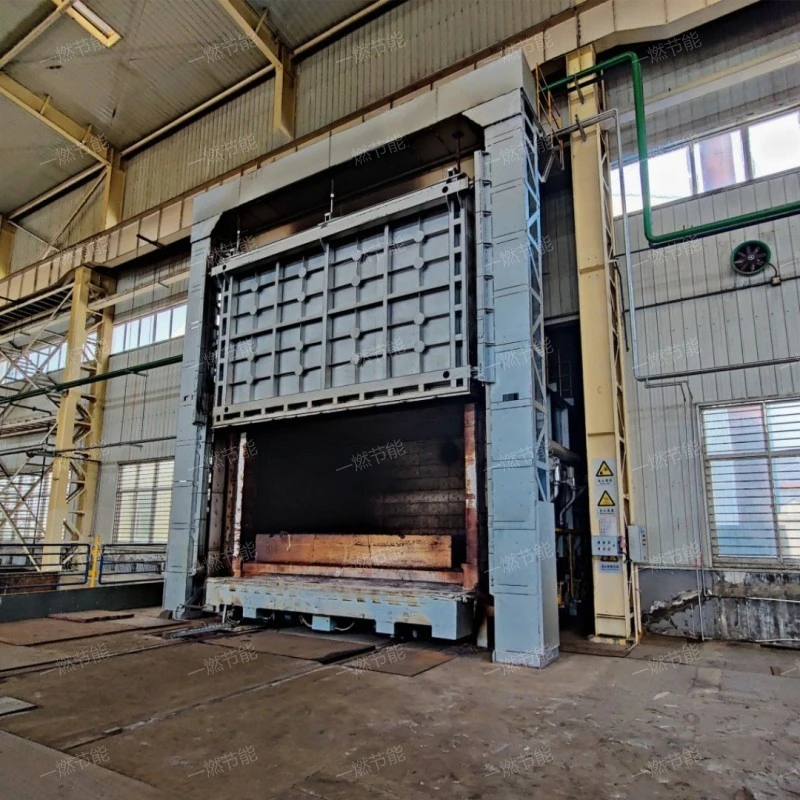

2、Forged heating furnace flue gas denitrification equipment field real shot

Exquisite design, excellent material selection, reliable quality and high-definition pictures for our customers to visit.。

Forged heating furnace flue gas denitrification equipment

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Forged heating furnace flue gas denitrification equipment structure

The Forged heating furnace flue gas denitrification equipment structure is introduced as follows:

- Catalytic reduction reaction

- Flue gas mixing and distribution system

- Reactor

- Reducing agent supply

- control system

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Ensure that the flue gas and reducing agent are fully mixed in the reactor to improve the denitrification efficiency.

It is the core component of Forged heating furnace flue gas denitrification equipment technology, and it is equipped with catalyst to promote the chemical reaction between reductant and NOx.

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

The whole Forged heating furnace flue gas denitrification equipment is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

Forged heating furnace flue gas denitrification equipment

4、Forged heating furnace flue gas denitrification equipment video

Speak directly with facts on the spot。

Forged heating furnace flue gas denitrification equipment

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd Simple structure and advanced technology.,structure mainly includes: Catalyst supply system, control system, Flue gas mixing and distribution system, Temperature control and monitoring system, Catalyst reactor and so on。

5、Forged heating furnace flue gas denitrification equipment principle

Forged heating furnace flue gas denitrification equipmentUnder the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,It has the functions of environmental protection, environmental protection, Flue gas denitrification, Promote sustainable development and Improve product quality,features include Strong adaptability, Efficient denitration, Strong adaptability, Environmental protection and pollution-free and Stable operation,the main structure includes Catalyst supply system, control system, Temperature control and monitoring system, Flue gas mixing and distribution system, Catalyst reactor and so on,Forged heating furnace flue gas denitrification equipmentThe overall structural design is simple, diverse and beautiful.,be loved by our customers.。

Forged heating furnace flue gas denitrification equipment

6、One-combustion energy saving company service

One-combustion energy saving manufacturer services include three aspects: pre-sale, in-sale and after-sale. Each stage is closely connected with each other, sincerely serving each customer, focusing on customer needs, providing customers with product knowledge training and regularly repairing products for customers, etc., which has been appreciated by new and old customers.。

One-combustion energy saving

Forged heating furnace flue gas denitrification equipmentit has the characteristics of Good selectivity, Stable operation, Economically feasible, energy saving and environmental protection and Environment friendly,the product looks beautiful.。

Related recommendation

-

Introduction to Heating trolley forging heating furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Pressure vessel trolley forging furnace, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Continuous heat treatment industrial furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

What is a Regenerative tube heating furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Medium high temperature trolley heating furnace and heating furnace structure principle

2025-5-27 -

What is a Split type well tube furnace? How much is the price of the forging furnace?

2025-5-27 -

Introduction to Energy saving and environmentally friendly tubular roaster and heating furnace structure principle

2025-5-27 -

Introduction to Strip steel heating furnace and forging furnace working principle

2025-5-27 -

What is a Regenerative gas trolley heating furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Gas storage tubular roaster? Introduction to the Working Principle of heating furnace

2025-5-27