Introduction to Catalytic reduction low-temperature denitrification and SCR denitration advantages and features

Catalytic reduction low-temperature denitrificationthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,Widely used inenvironmental protection,Improve product quality,Meet the requirements of environmental protection,Promote sustainable development,Meet the requirements of environmental protection and so on,can be customized according to user's needs.。

1、Brief introduction of Catalytic reduction low-temperature denitrification

Catalytic reduction low-temperature denitrificationthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.,at the start of the operation,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,It has the functions of Improve product quality, Flue gas denitrification, environmental protection, Promote sustainable development and Meet the requirements of environmental protection,the main structure includes Flue gas mixing and distribution system, Catalyst reactor, control system, Temperature control and monitoring system and Catalyst supply system,widely used inmetallurgy,Gas power plant,Gas power plant,cement plant,iron and steel plant and other industries。

Catalytic reduction low-temperature denitrification

2、Working principle of Catalytic reduction low-temperature denitrification

Catalytic reduction low-temperature denitrificationthe principle is simple.Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,the product looks atmospheric.,is a common Catalytic reduction low-temperature denitrification,is designed by One-combustion energy saving with advanced technology。

Catalytic reduction low-temperature denitrification

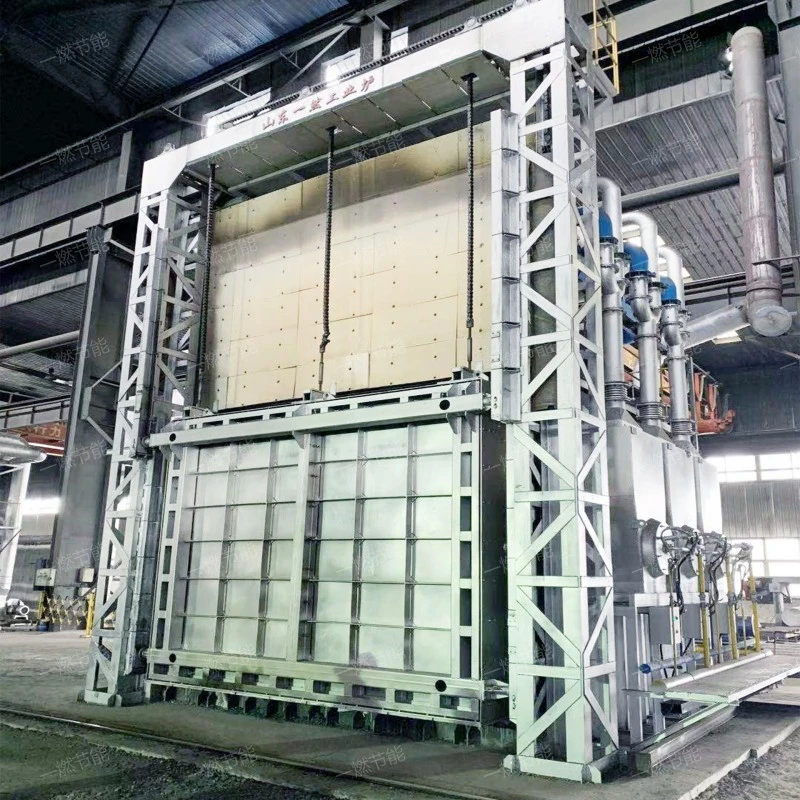

3、Catalytic reduction low-temperature denitrification picture

One-combustion energy saving Catalytic reduction low-temperature denitrificationthe product looks beautiful., the picture is taken.。

Catalytic reduction low-temperature denitrification

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Catalytic reduction low-temperature denitrification structure composition

The Catalytic reduction low-temperature denitrification structure is introduced as follows:

- Reducing agent supply

- Catalytic reduction reaction

- Reducing agent storage and supply system

- control system

- Temperature control and monitoring system

Reducing agents such as liquid pure ammonia or ammonia water (aqueous solution of ammonia) are evaporated and mixed with diluted air or flue gas.

Under the action of catalyst, the reductant and NOx in flue gas undergo selective catalytic reduction reaction to generate nitrogen and water vapor.

Used to store and supply reducing agent (such as ammonia or urea solution) to the reactor.

The whole Catalytic reduction low-temperature denitrification is automatically controlled, including the adjustment of reducing agent supply, flue gas flow and temperature, so as to ensure the stable operation of the system and achieve the expected denitrification effect.

It is used to monitor and control the temperature of the reactor to ensure that the chemical reaction is carried out in the optimal temperature range.

Catalytic reduction low-temperature denitrification

5、Catalytic reduction low-temperature denitrification quotation

The Catalytic reduction low-temperature denitrification price is introduced as follows:

- Configuration difference

- Different regions

- Cost input

- Service factor

- regional difference

The difference in Catalytic reduction low-temperature denitrification configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

If the location of the manufacturer is superior, its transportation will be more convenient. One-combustion energy saving detailed address:Zhangqiu Niu Yi Industrial Park, Ji 'nan City, Shandong Province has convenient transportation, which provides a good convenience for the transportation of Catalytic reduction low-temperature denitrification.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Catalytic reduction low-temperature denitrification manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Catalytic reduction low-temperature denitrification price can meet the purchasing needs of customers.

The consumption level will be different in different regions. When pricing equipment, many manufacturers often set the price according to the consumption level of the region. If the consumption level is high, the price will be correspondingly high, otherwise, the price will be very low.

Catalytic reduction low-temperature denitrification

6、One-combustion energy saving company discount

Catalytic reduction low-temperature denitrification is a new type of SCR denitration introduced by One-combustion energy saving manufacturer, which has a wide range of applications, complete structural design and high working efficiency. It is an ideal equipment for building materials and other industries. Now consult One-combustion energy savingCatalytic reduction low-temperature denitrification, you can enjoy the discount, and there are many activities for you, such as full reduction and full reduction。

One-combustion energy saving

Catalytic reduction low-temperature denitrificationis a kind of high quality and low price Catalytic reduction low-temperature denitrification,that is, selective catalytic reduction technology is a technology used to reduce the emission of nitrogen oxides in flue gas.,the product looks beautiful.。

Related recommendation

-

What is a Annealing heat treatment resistance furnace? Introduction to the advantages, characteristics, and principles of the Trolley resistance heating furnace

2025-5-27 -

Introduction to Plate chain annealing furnace and forging furnace advantages and features

2025-5-27 -

Introduction to Automatic temperature control through heating furnace and Forging furnace advantages and features

2025-5-27 -

What is a Roller shaft quenching heat treatment furnace? Introduction to the advantages and characteristics of heating furnace functions

2025-5-27 -

What is a Automatic controlled greenhouse heating furnace? How much is the price of the Forging furnace?

2025-5-27 -

Introduction to Aluminum alloy continuous heating resistance heating furnace and Trolley resistance furnace advantages and features

2025-5-27 -

What is a Large stainless steel annealing resistance furnace? Introduction to the advantages, characteristics, and principles of the Trolley resistance heating furnace

2025-5-27 -

Introduction to Carburizing and tempering industrial furnace, how much is the price of the Forging furnace?

2025-5-27 -

Introduction to SCR flue gas catalytic flue gas denitrification, advantages, characteristics and principles of SCR flue gas denitrification

2025-5-27 -

What is a SCR oxidation denitrification system? Introduction to the advantages and characteristics of the SCR denitration system

2025-5-27