Introduction to Medium temperature well quenching furnace and heating furnace working principle

Medium temperature well quenching furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、Efficient combustion and waste heat recovery system can significantly reduce energy consumption, thus reducing operating costs.、The use of clean and environmentally friendly natural gas as fuel effectively avoids the adverse effects of chemical reactions between impurities such as coal-fired furnaces and forgings during heating. At the same time, natural gas has high calorific value and high combustion temperature, and the combustion temperature can be further increased by preheating air and fuel. In addition, the gas forging heating furnace also has good heat loss control ability and intelligent control system, which can accurately adjust the ratio of air to natural gas, ensure full combustion of natural gas, and reduce mechanical incomplete combustion and chemical incomplete combustion.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.。The following is to introduce the Medium temperature well quenching furnace:

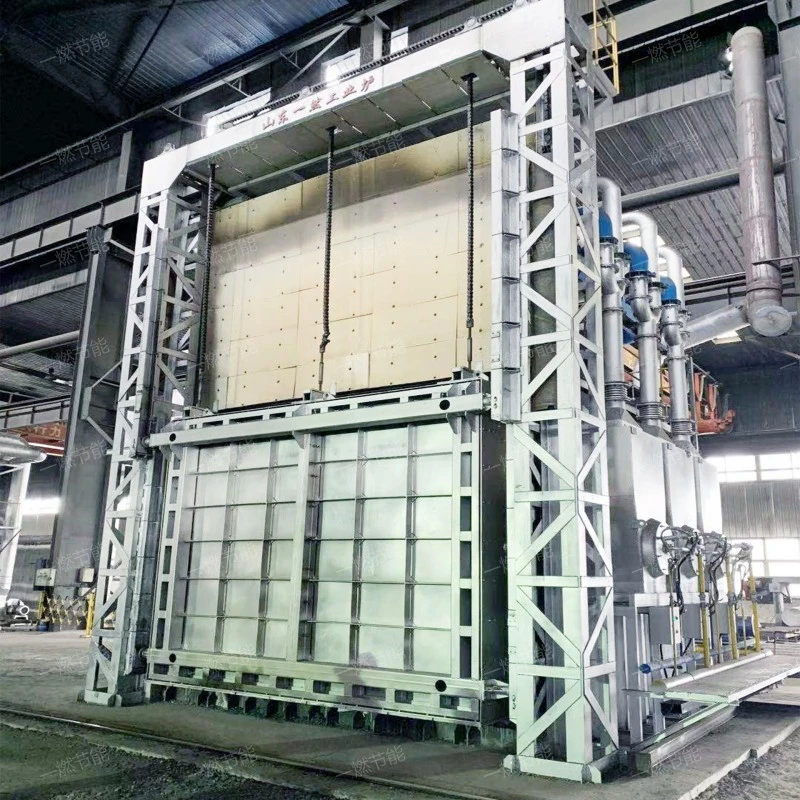

1、Brief introduction of Medium temperature well quenching furnace

Medium temperature well quenching furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it has been widely used in heat treatment, light industry, material, war industry, chemical industry and other industries,at the start of the operation,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,is a kind of high quality and low price Medium temperature well quenching furnace,has been favored by more and more customers.。

Medium temperature well quenching furnace

2、Structural characteristics of Medium temperature well quenching furnace

The Medium temperature well quenching furnace structure is introduced as follows:

- ventilation system

- Radiation chamber

- furnace chamber

- combustor

- convection chamber

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The heat load of the main place for Medium temperature well quenching furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

Medium temperature well quenching furnace

3、Medium temperature well quenching furnace function

Medium temperature well quenching furnaceit has the functions of heat treatment, anneal, quench, heat treatment and normalizing,is a popular Medium temperature well quenching furnace,Mainly used forMetal tempering,Metal heat treatment,Energy conservation and environmental protection,Metal melting and casting andMetal forging heating。

Medium temperature well quenching furnace

4、Working principle of Medium temperature well quenching furnace

Medium temperature well quenching furnaceat work,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,multifunctional, with functions such as temper, quench, Casting heating, normalizing and heat treatment。

Medium temperature well quenching furnace

5、Medium temperature well quenching furnace price concessions

The Medium temperature well quenching furnace price is introduced as follows:

- brand

- product function

- Manufacturer's strength

- Model specification

- select a qualified person

Different brands of products in the same series have more or less differences in product prices, and different brands of Medium temperature well quenching furnace have more or less differences in price.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

Our factory has mature and perfect production technology, advanced and intelligent processing technology, abundant labor resources and low investment. Coupled with the influence of special geographical location, our company has invested much less in manpower, material resources and financial resources than other manufacturers.

Because there are many specifications and models of Medium temperature well quenching furnace, the quotations of Medium temperature well quenching furnace with different specifications and models are different.

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

Medium temperature well quenching furnace

6、One-combustion energy saving service

Service has a starting point, and satisfaction has no end. One-combustion energy saving provides services such as free design scheme before sale, free installation and debugging of products during sale, and regular return visits after sale to solve customer problems in time. If you have special requirements for products, manufacturers also support tailor-made.。

One-combustion energy saving

Medium temperature well quenching furnaceit can be used in electron, building materials, Machinery manufacturing, machinery, pharmacy and other industries,multifunctional, with functions such as Forging heating, temper, Casting heating, anneal and hardening and tempering,at the start of the operation,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Related recommendation

-

Introduction to Multi chamber quenching furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

Introduction to Full fiber trolley heating furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

What is a Regenerative burner chain grate furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Rapid spheroidization annealing heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

台车炭化炉

2023-05-04 -

What is a Fully automatic well type heating furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction and advantages of Rolling mill natural gas trolley furnace

2025-6-18 -

Introduction to Gas storage chain annealing furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Chain track spheroidization annealing furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Side discharge forging heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27