Introduction to Environmentally friendly roller bottom furnace, introduction to Forging furnace advantages and characteristics

Environmentally friendly roller bottom furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,be of high quality,low in price。

1、Brief introduction of Environmentally friendly roller bottom furnace

Environmentally friendly roller bottom furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,the product looks atmospheric.,the advantage is The metal material can be heated to the required temperature in a short time, and the production efficiency is improved.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、Suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.,be loved by our customers.。

Environmentally friendly roller bottom furnace

2、Environmentally friendly roller bottom furnace performance advantage

The advantages of Environmentally friendly roller bottom furnace are as follows:

- Reduce operating costs

- Extend the service life of equipment

- Multiple fuel options

- Reduce operating costs

- Wide application range

The efficient combustion and waste heat recovery system of the Environmentally friendly roller bottom furnace can significantly reduce energy consumption, thus reducing operating costs.

The Environmentally friendly roller bottom furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

Although the Environmentally friendly roller bottom furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The efficient combustion and waste heat recovery system of the Environmentally friendly roller bottom furnace can significantly reduce energy consumption, thus reducing operating costs.

The Environmentally friendly roller bottom furnace is suitable for forging and heating of various metal materials, including steel, aluminum and copper. At the same time, it can also be used in metal heat treatment, tempering and other technological processes.

Environmentally friendly roller bottom furnace

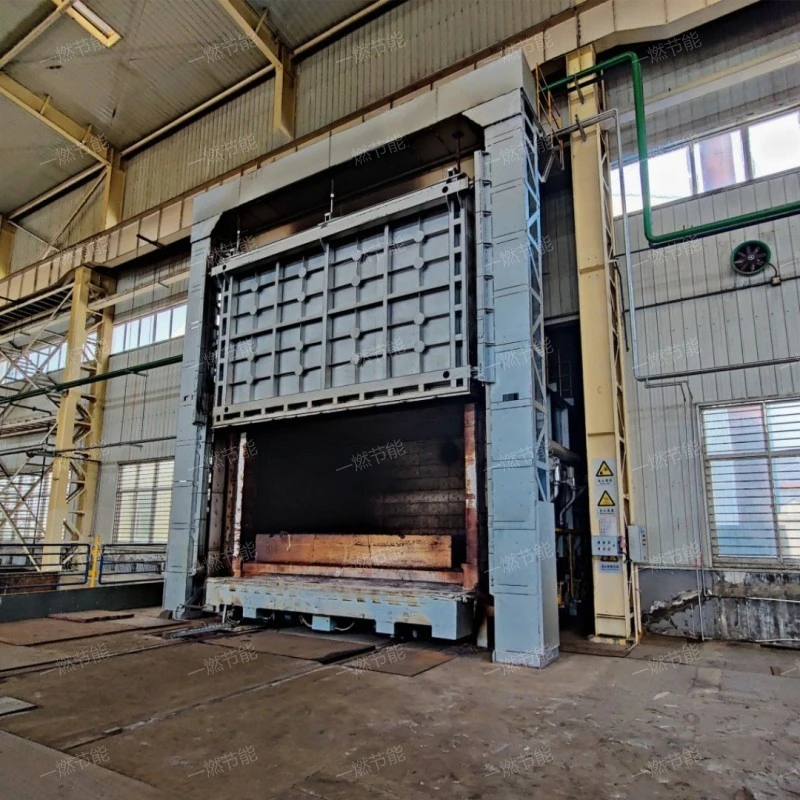

3、Environmentally friendly roller bottom furnace HD real shot

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site Environmentally friendly roller bottom furnacet operation, and helps customers to deeply understand the Environmentally friendly roller bottom furnace production process and production site, and gain favorable comments and recognition from customers.。

Environmentally friendly roller bottom furnace

As you can see from the live video.,One-combustion energy saving the product looks atmospheric.。

4、Environmentally friendly roller bottom furnace HD real picture

Beautiful design, excellent material selection and excellent quality.。

Environmentally friendly roller bottom furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

5、Environmentally friendly roller bottom furnace characteristics

The Environmentally friendly roller bottom furnace features are as follows:

- Efficient heating

- Easy to control

- Strong adaptability

- Stable and reliable

- Easy to control

The Environmentally friendly roller bottom furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The Environmentally friendly roller bottom furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

The Environmentally friendly roller bottom furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The combustion system and ventilation system of the Environmentally friendly roller bottom furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

Environmentally friendly roller bottom furnace

6、How much is the Environmentally friendly roller bottom furnace?

The Environmentally friendly roller bottom furnace price is introduced as follows:

- Reasonable sales model

- market competition

- service

- regional difference

- product costs

Direct-selling manufacturers are cheaper than second-and third-tier dealers because the former earns the difference without going through middlemen; Online sales are cheaper than offline sales, because you need to invest in store fees, employee fees and other related expenses in the later stage; Close-distance sales are cheaper than long-distance sales because the latter consumes a lot of transportation costs.

The market demand has a certain impact on the price of Environmentally friendly roller bottom furnace. When there are many customers who need Environmentally friendly roller bottom furnace in the market, there will be a phenomenon that demand exceeds supply, and then the price of Environmentally friendly roller bottom furnace will become higher. On the contrary, when there are very few customers who need Environmentally friendly roller bottom furnace, there will be a phenomenon of oversupply, and the price of Environmentally friendly roller bottom furnace will be reduced.

Service factors always affect the sales price of products, and high-quality service will make customers have greater satisfaction and recognition. The service factors mainly include pre-sales service, in-sales service and after-sales service. For each stage of service, our company takes the price factor into account and makes a reasonable judgment between service and price, so that the Environmentally friendly roller bottom furnace price and service can meet the actual needs of customers.

If the location of the manufacturer is superior, its transportation will be more convenient. One-combustion energy saving address:Shandong(Province) has convenient transportation, which provides a good convenience for the transportation of Environmentally friendly roller bottom furnace.

Cost is a direct and fundamental factor that affects the price of Environmentally friendly roller bottom furnace. The manufacturing cost is reflected in the capital investment spent on raw materials, labor and technology, which is high in cost, high in Environmentally friendly roller bottom furnace price, low in cost and low in price.

Environmentally friendly roller bottom furnace

Environmentally friendly roller bottom furnacethe main features are Strong adaptability, Strong adaptability, Easy to control, energy saving and environmental protection and Easy to maintain,multifunctional, with functions such as heat treatment, Forging heating, Casting heating, Forging heating and temper。

Related recommendation

-

Introduction to Low temperature quenching and tempering industrial furnace and heating furnace working principle

2025-5-27 -

Introduction to Stick style spheroidization annealing furnace, advantages, characteristics and principles of forging furnace

2025-5-27 -

What is a Low temperature tube roasting furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Casting heat treatment trolley heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Casting forging furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Intelligent resistance furnace, Trolley resistance heating furnace advantages, characteristics and principles

2025-5-27 -

What is a Forging furnace flue gas denitrification system? How much is the price of the SCR denitration?

2025-5-27 -

Introduction to Roasting tube annealing furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

What is a Car steel pipe annealing furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

What is a Gas storage chain furnace? Introduction to the principle of heating furnace structure

2025-5-27