What is a Roller type heating furnace? Introduction to the principle of heating furnace structure

Roller type heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,the product looks atmospheric.,The overall structural design is simple and novel.,it is mainly composed of ventilation system, Radiation chamber, combustor, ventilation system and recovery of waste heat。The following is to introduce the Roller type heating furnace:

1、Brief introduction of Roller type heating furnace

Roller type heating furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,Widely used in Metal tempering, Improve production efficiency, Energy conservation and environmental protection, Metal melting and casting and Metal forging heating,multifunctional, with functions such as hardening and tempering, anneal, temper, Forging heating and anneal。

Roller type heating furnace

2、Roller type heating furnace function

Roller type heating furnaceit has the functions of heat treatment, normalizing, Casting heating, hardening and tempering and quench,it mainly includes furnace chamber, convection chamber, ventilation system, Radiation chamber and ventilation system,the main features are Easy to control, energy-efficient, energy saving and environmental protection, Easy to maintain and Stable and reliable。

Roller type heating furnace

3、Working principle of Roller type heating furnace

Roller type heating furnaceat work,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,It can be used for Metal heat treatment, Improve production efficiency, Metal tempering, Energy conservation and environmental protection, Metal tempering, Energy conservation and environmental protection and so on。

Roller type heating furnace

4、Roller type heating furnace characteristics

The Roller type heating furnace features are as follows:

- Efficient heating

- Easy to control

- Efficient heating

- Stable and reliable

- Strong adaptability

The Roller type heating furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The Roller type heating furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Roller type heating furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Roller type heating furnace is suitable for forging and heating of various metal materials and has a wide range of applications.

Roller type heating furnace

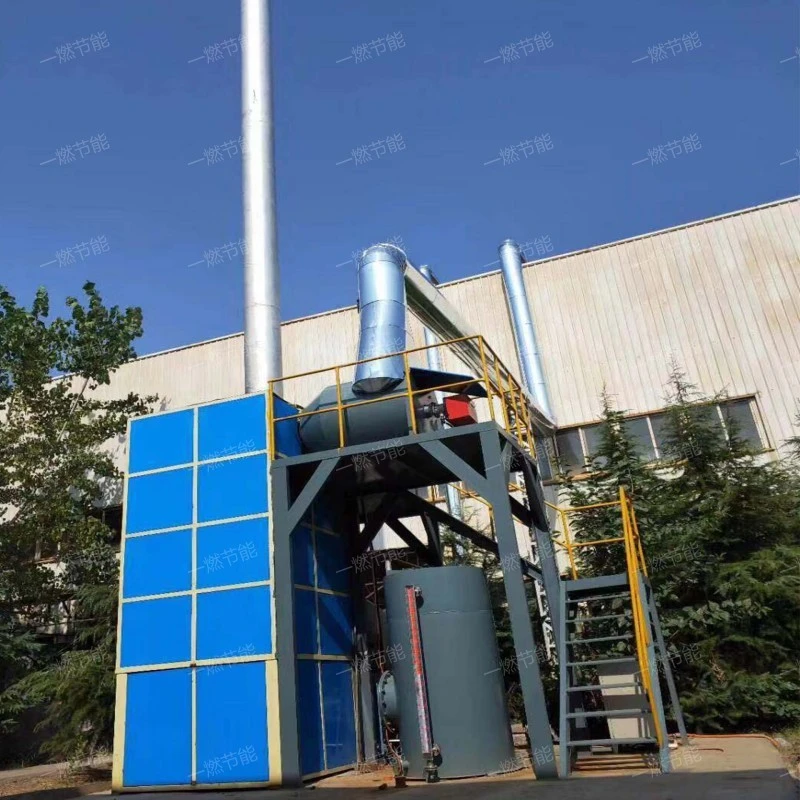

5、Roller type heating furnace HD picture real shot

Roller type heating furnace are widely used. The following is a multi-directional display diagram of Roller type heating furnace, and the details are full of quality and intelligence.。

Roller type heating furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、Roller type heating furnace price consultation

The Roller type heating furnace price is introduced as follows:

- product function

- raw material

- technology content

- Configuration difference

- Manufacturer's strength

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. One-combustion energy saving has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

One-combustion energy saving is a self-produced and self-sold Roller type heating furnace, and has rich experience in the production and manufacturing of Roller type heating furnace. In the process of production and manufacturing, there is less waste of resources, and the corresponding product prices are also low.

Roller type heating furnace

Roller type heating furnaceit is widely used in pharmacy, shipping, chemical industry, heat treatment, electron and other industries,at runtime,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.。

Related recommendation

-

What is a Automatic high-temperature trolley furnace? How much is the price of the Forging furnace?

2025-5-27 -

Introduction to Roasting tube annealing furnace, forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Roaster denitration system, how much is the price of the SCR denitration system?

2025-5-27 -

What is a Continuous quenching furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Carbon steel heating furnace, heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Low temperature catalytic reduction denitrification, SCR denitration specifications, model parameters

2025-5-27 -

Introduction to Double chamber quenching furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

What is a Electric heating and heat treatment furnace? Introduction to the advantages and characteristics of Trolley electric heating furnace functions

2025-5-27 -

环形天然气台车炉

2023-08-24 -

Introduction to Automated well tube furnace and Forging furnace structure principle

2025-5-27