What is a Fully automatic trolley furnace? Introduction to the advantages, characteristics, and principles of the Forging furnace

Fully automatic trolley furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,is a popular Fully automatic trolley furnace,reliable quality。The following is to introduce the Fully automatic trolley furnace:

1、Brief introduction of Fully automatic trolley furnace

Fully automatic trolley furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,has been favored by more and more customers.。

Fully automatic trolley furnace

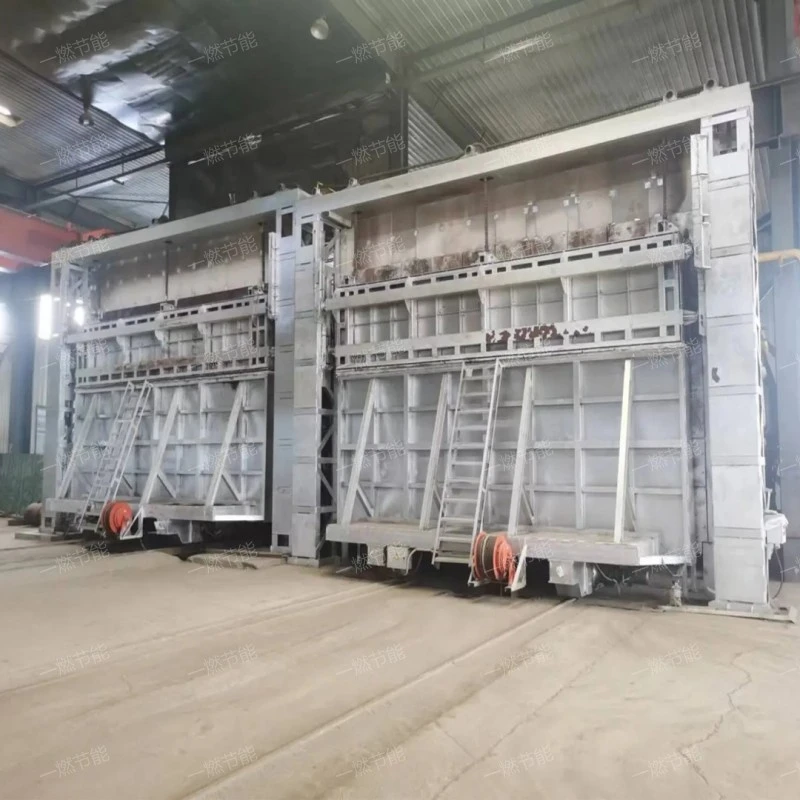

2、Fully automatic trolley furnace field real shot

Fully automatic trolley furnace HD factory map, all-round shooting, for our customers to visit.。

Fully automatic trolley furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

3、Fully automatic trolley furnace function

Fully automatic trolley furnacemultifunctional, with functions such as Casting heating, anneal, quench, Forging heating and heat treatment,super quality and competitive price。

Fully automatic trolley furnace

4、Introduction of Fully automatic trolley furnace characteristics

Fully automatic trolley furnace has the following characteristics

- Easy to maintain

- Stable and reliable

- Easy to control

- Strong adaptability

- energy saving and environmental protection

The structural design of the Fully automatic trolley furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Fully automatic trolley furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The combustion system and ventilation system of the Fully automatic trolley furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Fully automatic trolley furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

As a clean energy source, natural gas produces less pollutants after combustion, which is beneficial to environmental protection. At the same time, the application of waste heat recovery system further improves the energy utilization efficiency.

Fully automatic trolley furnace

5、Fully automatic trolley furnace price concessions

The Fully automatic trolley furnace price is introduced as follows:

- company strength

- select a qualified person

- Configuration difference

- technology

- Sales model

One-combustion energy saving's scale and strength are relatively strong, the technology and technology of products produced by manufacturers are relatively advanced, and there is less waste of resources in the process of manufacturing, and the price of products will be relatively low.

The raw materials used by manufacturers of different products will definitely be different. Some manufacturers use good raw materials for processing, and the cost of producing and manufacturing products is definitely high. If the quality of products produced by manufacturers is not guaranteed and the materials used are not very good, then the production cost of products will be low, and the price will be very low.

The overall configuration has a great influence on the price. Generally speaking, the higher the configuration, the higher its cost input and the higher the selling price of the product, which is beyond doubt. One-combustion energy saving has made a comprehensive thinking on the overall configuration of products, and at the same time has strictly controlled the material selection and design of products, so the price of products with the same configuration can easily meet the actual purchasing needs of customers.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

Fully automatic trolley furnace

6、Brief introduction of One-combustion energy saving

Shandong yiran energy-saving environment protection co., ltd, located in Jinan, is a large Fully automatic trolley furnace manufacturer. The Fully automatic trolley furnace produced have good performance, low price, reasonable structure and excellent quality. The key is reasonable price. Welcome new and old customers to visit and buy.。

One-combustion energy saving

Fully automatic trolley furnaceusually used in machinery, building materials, aerospace, war industry, petroleum and other fields,it has the functions of quench, Forging heating, Casting heating, hardening and tempering and anneal,the product looks atmospheric.。

Related recommendation

-

Introduction to Rotary trolley forging furnace, how much is the price of the forging furnace?

2025-5-27 -

What is a Bright quenching industrial furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Quenching natural gas trolley furnace? How much is the price of the heating furnace?

2025-5-27 -

台车模具加热炉

2023-05-28 -

Introduction of Bright quenching furnace

2025-6-18 -

What is a Preheating trolley forging heating furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

What is a Catalyst based flue gas denitrification? Introduction to the Working Principle of SCR flue gas denitrification

2025-5-27 -

Introduction to Gas through forging heating furnace, how much is the price of the forging furnace?

2025-5-27 -

What is a Steel chain iron core annealing furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Catalyst reduction method for denitrification? SCR denitration specifications, models, and parameters

2025-5-27