What is a Gas tube annealing furnace? How much is the price of the Forging furnace?

Gas tube annealing furnaceIt is a kind of equipment that uses natural gas as fuel to heat metal materials and make them reach forging temperature.,Stable and reliable,energy saving and environmental protection,Strong adaptability,Easy to control,Easy to maintain。

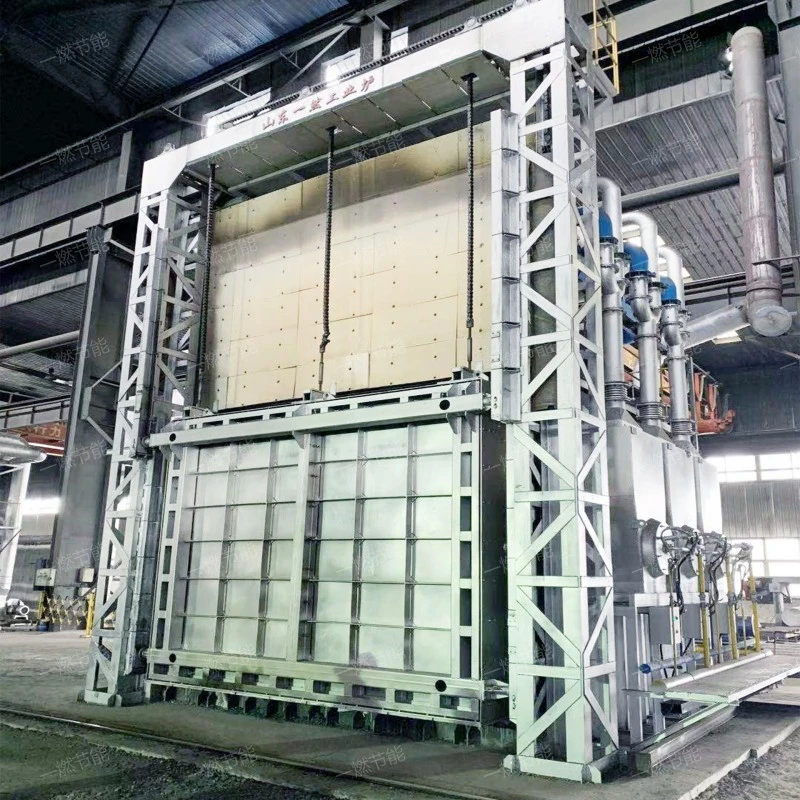

1、Brief introduction of Gas tube annealing furnace

Gas tube annealing furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,was developed and designed by One-combustion energy saving。

Gas tube annealing furnace

2、Introduction of Gas tube annealing furnace characteristics

Gas tube annealing furnace has the following characteristics

- energy saving and environmental protection

- Strong adaptability

- Efficient heating

- Stable and reliable

- Easy to maintain

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Gas tube annealing furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The Gas tube annealing furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The Gas tube annealing furnace can heat the metal material to the required temperature in a short time and improve the production efficiency.

The Gas tube annealing furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The structural design of the Gas tube annealing furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

Gas tube annealing furnace

3、Functional advantages of Gas tube annealing furnace

Gas tube annealing furnaces have the following advantages.

- Improve product quality

- Extend the service life of equipment

- Intelligent control

- Uniform heating

- Rapid temperature rise

Because the Gas tube annealing furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

The Gas tube annealing furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The Gas tube annealing furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The Gas tube annealing furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The Gas tube annealing furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

Gas tube annealing furnace

4、Gas tube annealing furnace function

Gas tube annealing furnacemultifunctional, with functions such as Forging heating, quench, anneal, hardening and tempering and anneal。

Gas tube annealing furnace

5、How much is the Gas tube annealing furnace?

The Gas tube annealing furnace price is introduced as follows:

- region

- technology

- select a qualified person

- regional difference

- market supply and demand

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

The quality of materials directly determines the cost. The worse the materials are, the lower the cost will be, and the cheaper the price will be. Of course, the materials are better and the cost is higher, so the overall quotation is naturally higher.

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

The difference between the supply and demand of manufacturers and customers will also affect the Gas tube annealing furnace price. When the demand of customers on the market increases and the supply of products by manufacturers is small, the Gas tube annealing furnace price will increase with the increase of demand. On the contrary, when the supply of product manufacturers on the market exceeds the demand of customers, the Gas tube annealing furnace price will decrease.

Gas tube annealing furnace

6、One-combustion energy saving introduced

One-combustion energy saving is a professional and large-scale Gas tube annealing furnace manufacturer, which has many years of production and operation, complete production facilities, skilled staff and high production capacity and product quality. It is a Gas tube annealing furnace manufacturer trusted by consumers at present.。

One-combustion energy saving

Gas tube annealing furnaceThe overall structural design is relatively simple,generally, it is composed of furnace chamber, recovery of waste heat, ventilation system, combustor, convection chamber and other major components,is a Gas tube annealing furnace,It is mostly used in Metal heat treatment, Metal tempering, Metal melting and casting, Metal forging heating, Energy conservation and environmental protection, Metal heat treatment and so on。

Related recommendation

-

What is a Automatic high-temperature trolley heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Stepping bottom automatic heating furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Multi chamber heat treatment furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction and advantages of Energy saving natural gas trolley furnace

2025-6-18 -

What is a Multi tube bright annealing furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Solid state heat treatment furnace? heating furnace specifications, models, and parameters

2025-5-27 -

Introduction to Roll quenching heat treatment furnace and Forging furnace advantages and features

2025-5-27 -

Introduction to Dual regenerative walking furnace and heating furnace working principle

2025-5-27 -

What is a Continuous roller heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Denitrification in the forging industry and SCR denitration advantages and features

2025-5-27