What is a Indirect roasting furnace? How much is the price of the heating furnace?

Indirect roasting furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,widely used in petroleum, metallurgy, heat treatment, machinery, aerospace and other fields,in the course of work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,it has the structure of recovery of waste heat, combustor, convection chamber, ventilation system and furnace chamber,This Indirect roasting furnaceThe structural design is more advanced and reasonable.,is a kind of Indirect roasting furnace manufactured by One-combustion energy saving。

1、Brief introduction of Indirect roasting furnace

Indirect roasting furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,it has been widely used in Household necessities, automobile, war industry, shipping, light industry and other industries,the product looks atmospheric.,is based on One-combustion energy saving is an advanced Indirect roasting furnace developed by our company in combination with the actual situation of the industry。

Indirect roasting furnace

2、Indirect roasting furnace structure composition

The Indirect roasting furnace has the following structure

- Waste heat recovery system

- combustor

- convection chamber

- Radiation chamber

- Waste heat recovery system

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

The material is heated by convection heat transfer of high temperature flue gas discharged from the radiation chamber. Flue gas washes the tube wall of the furnace tube at a high speed to carry out effective convection heat transfer, and its heat load accounts for about 20%-30% of the whole furnace. The convection chamber is generally arranged above the radiation chamber, and some are placed on the ground alone. In order to improve the heat transfer effect, nail head tubes or finned tubes are often used in furnace tubes.

The heat load of the main place for Indirect roasting furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Indirect roasting furnace

3、Functional advantages of Indirect roasting furnace

Indirect roasting furnaces have the following advantages.

- Extend the service life of equipment

- Improve product quality

- Multiple fuel options

- Uniform heating

- Extend the service life of equipment

The Indirect roasting furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

Because the Indirect roasting furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

Although the Indirect roasting furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The Indirect roasting furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

The Indirect roasting furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

Indirect roasting furnace

4、Indirect roasting furnace explanation video

On-site aerial photography of Indirect roasting furnace。

Indirect roasting furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd it is mainly composed of Radiation chamber, convection chamber, ventilation system, furnace chamber and Radiation chamber。

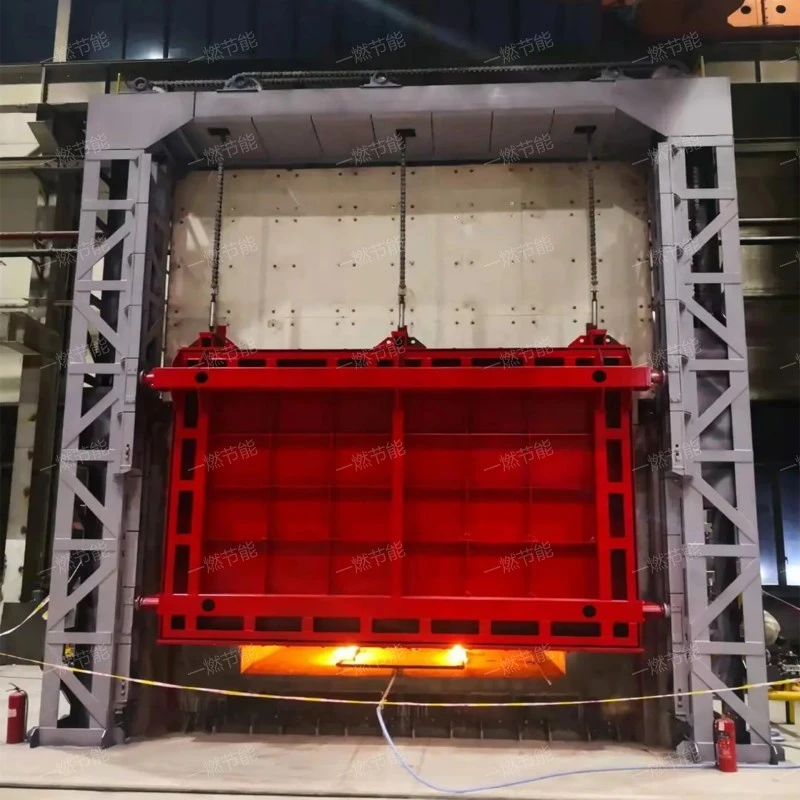

5、Physical picture of Indirect roasting furnace

High-definition picture display of Indirect roasting furnace, excellent material selection, reliable quality and trustworthy.。

Indirect roasting furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

6、Indirect roasting furnace price consultation

The Indirect roasting furnace price is introduced as follows:

- select a qualified person

- manufacturing cost

- product configuration

- brand

- Product technology

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

When it comes to cost, I believe everyone has heard the saying "You get what you want for a price", which shows that the upfront cost of a product is directly proportional to its value. The upfront cost is high, the value is high, the quality is good, and the price is naturally high. The less the cost is, the lower the price is, and the quality is not good.

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. One-combustion energy saving pays special attention to the hardware configuration of products, so One-combustion energy saving Indirect roasting furnace has a higher cost performance.

Different brands of products in the same series have more or less differences in product prices, and different brands of Indirect roasting furnace have more or less differences in price.

High-tech products need more advanced technology to support them, so products with higher performance will also lead to a general increase in their prices, and vice versa.

Indirect roasting furnace

Indirect roasting furnaceIt has the functions of Energy conservation and environmental protection, Metal melting and casting, Metal tempering, Metal forging heating and Improve production efficiency,features include Easy to control, energy-efficient, energy saving and environmental protection, Easy to control and Stable and reliable。

Related recommendation

-

Introduction to Intelligent resistance furnace, Trolley resistance heating furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Quenching furnace chamber type and forging furnace advantages and features

2025-5-27 -

Introduction to Large stainless steel annealing resistance heating furnace, Trolley resistance furnace specifications, model parameters

2025-5-27 -

What is a Round tube continuous heating furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

What is a Steel casting heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Automatic lifting resistance furnace? How much is the price of the Trolley resistance heating furnace?

2025-5-27 -

Introduction to Automatic temperature regulating box furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

What is a Aluminum alloy high-temperature trolley forging heating furnace? Introduction to the principle of Forging furnace structure

2025-5-27 -

What is a Environmentally friendly through forging heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to multi-zone reheating furnace, forging furnace specifications, model parameters

2025-5-27