What is a Fully automatic quenching and heating furnace? Forging furnace specifications, models, and parameters

Fully automatic quenching and heating furnaceIt is a forging heating device using gas as fuel.,is a Fully automatic quenching and heating furnace,is carefully developed by One-combustion energy saving combined with advanced technology。The following is to introduce the Fully automatic quenching and heating furnace:

1、Brief introduction of Fully automatic quenching and heating furnace

Fully automatic quenching and heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

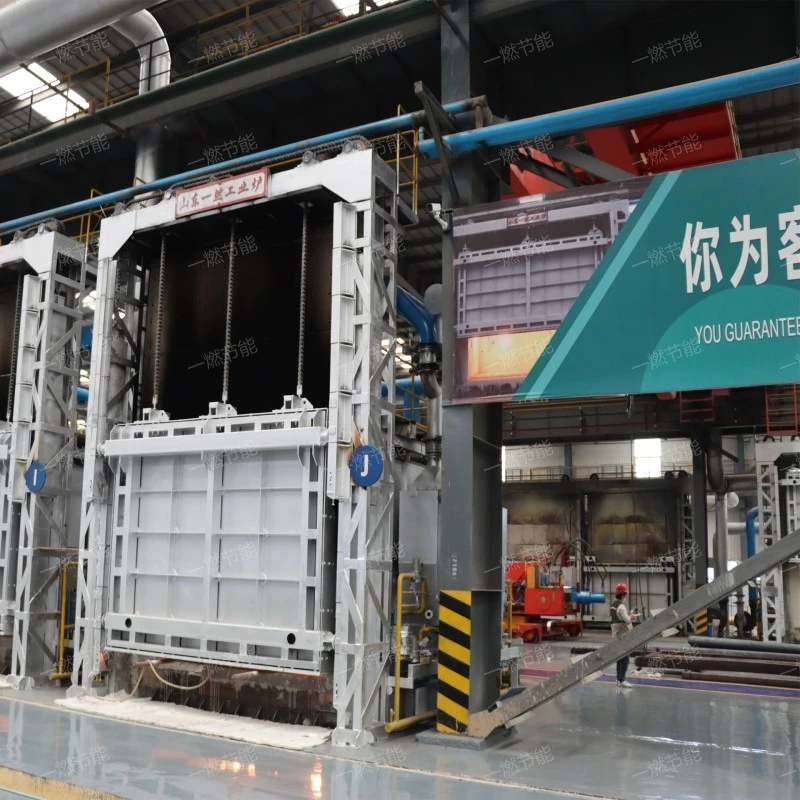

Fully automatic quenching and heating furnace

2、Introduction of Fully automatic quenching and heating furnace characteristics

Fully automatic quenching and heating furnace has the following characteristics

- Easy to maintain

- Efficient heating

- energy saving and environmental protection

- Easy to control

- Strong adaptability

The structural design of the Fully automatic quenching and heating furnace is reasonable and easy to maintain, which reduces the operating cost and failure rate of the equipment.

The Fully automatic quenching and heating furnace can heat the metal to the required forging temperature in a very short time, reducing the loss caused by the oxidation of the metal.

As a clean energy source, gas produces less waste gas and waste smoke after combustion, which is beneficial to environmental protection. At the same time, some Fully automatic quenching and heating furnaces are also equipped with waste heat recovery system, which further improves the energy utilization efficiency.

The combustion system and ventilation system of the Fully automatic quenching and heating furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

The Fully automatic quenching and heating furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

Fully automatic quenching and heating furnace

3、Advantages of Fully automatic quenching and heating furnace principle

Fully automatic quenching and heating furnaceThe high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,it is widely used in electron, Household necessities, metallurgy, surface treatment, war industry and other industries,the main structure includes recovery of waste heat, ventilation system, convection chamber, combustor and furnace chamber,Fully automatic quenching and heating furnaceSimple structure and reliable operation.。

Fully automatic quenching and heating furnace

4、Fully automatic quenching and heating furnace video

You can buy Fully automatic quenching and heating furnace according to your needs and show you Fully automatic quenching and heating furnace videos.。

Fully automatic quenching and heating furnace

As you can see from the live video.,Shandong yiran energy-saving environment protection co., ltd It is an efficient, energy-saving and environment-friendly metal heating device.。

5、Fully automatic quenching and heating furnace structure composition

The Fully automatic quenching and heating furnace structure is introduced as follows:

- furnace chamber

- Waste heat recovery system

- convection chamber

- combustor

- furnace chamber

A space for holding metallic materials for heating.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

A space for holding metallic materials for heating.

Fully automatic quenching and heating furnace

6、Fully automatic quenching and heating furnace price concessions

The Fully automatic quenching and heating furnace price is introduced as follows:

- Different regions

- Product technology

- Configuration difference

- raw material

- Proper management mode

Geographical location also has a certain influence on the formulation of price, because there is a close relationship between geographical location and transportation cost. Generally, the price of places with superior geographical location will be more fair, which is lower than that of those remote cities. One-combustion energy saving detailed address:Zhangqiu Niu Yi Industrial Park, Ji 'nan City, Shandong Province, where the traffic is very developed and convenient, provides a series of conveniences for the distribution of products to a great extent.

Different manufacturers have different advanced technologies, different production processes and different performances, and the price difference is naturally quite large.

The higher the hardware configuration, the greater the product cost, so the sales price of such products will be higher. One-combustion energy saving pays special attention to the hardware configuration of products, so One-combustion energy saving Fully automatic quenching and heating furnace has a higher cost performance.

The quality of material selection is one of the main factors that directly affect the Fully automatic quenching and heating furnace. If the quality of material selection is better, the price may be more expensive. Therefore, customers must first understand the quality of material selection before purchasing products, and then compare whether the quality and price match.

If there is no middleman to earn the difference, then the Fully automatic quenching and heating furnace price will naturally decrease. One-combustion energy saving adopts the business model of "self-production and self-marketing" to sell products, thus realizing "one-on-one" sales, so the comprehensive price of our products is relatively high.

Fully automatic quenching and heating furnace

Fully automatic quenching and heating furnaceThe structural design is more advanced and reasonable.,it is mainly composed of Radiation chamber, ventilation system, convection chamber, ventilation system and Radiation chamber,It is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,is a popular Fully automatic quenching and heating furnace。

Related recommendation

-

Introduction to Continuous bright annealing heat treatment furnace, introduction to forging furnace advantages and characteristics

2025-5-27 -

What is a SCR catalytic oxidation flue gas denitrification equipment? How much is the price of the SCR denitration system?

2025-5-27 -

Introduction to Catalytic reduction low-temperature flue gas denitrification equipment and SCR denitration system structure principle

2025-5-27 -

What is a Pressure type annealing heating furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to SCR catalytic oxidation flue gas denitrification system and SCR denitration advantages and features

2025-5-27 -

Introduction to Automatic temperature control tube heating furnace and Forging furnace structure principle

2025-5-27 -

Introduction to Spheroidization annealing electric furnace and Trolley electric heating furnace working principle

2025-5-27 -

What is a Gas storage roller furnace? Introduction to the Working Principle of forging furnace

2025-5-27 -

Introduction to Well type high-temperature quenching furnace and Forging furnace working principle

2025-5-27 -

Introduction to Low temperature catalyst furnace external denitrification, introduction to SCR denitration system function advantages and characteristics

2025-5-27