Introduction to Direct heating annealing furnace and Forging furnace advantages and features

Direct heating annealing furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,is a popular Direct heating annealing furnace,support customization。The following is to introduce the Direct heating annealing furnace:

1、Brief introduction of Direct heating annealing furnace

Direct heating annealing furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.。

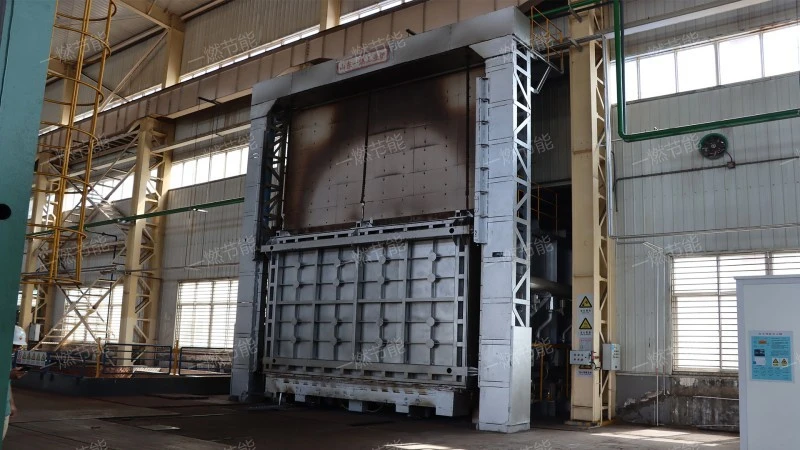

Direct heating annealing furnace

2、Working principle of Direct heating annealing furnace

Direct heating annealing furnaceat the start of the operation,The high-temperature flame and flue gas generated by burning gas (such as natural gas and liquefied petroleum gas) in the furnace are used as heat sources to heat metal materials.,is carefully developed by One-combustion energy saving combined with advanced technology。

Direct heating annealing furnace

3、Introduction of advantages of Direct heating annealing furnace

The advantages of Direct heating annealing furnace are as follows:

- clean energy

- Multiple fuel options

- Efficient combustion

- Extend the service life of equipment

- Reduce operating costs

Natural gas, as a clean energy source, produces less waste gas and dust after combustion, which has little pollution to the environment. This will help reduce industrial emissions and improve the atmospheric environment.

Although the Direct heating annealing furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

The Direct heating annealing furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Direct heating annealing furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

The efficient combustion and waste heat recovery system of the Direct heating annealing furnace can significantly reduce energy consumption, thus reducing operating costs.

Direct heating annealing furnace

4、Direct heating annealing furnace structure

The Direct heating annealing furnace structure is introduced as follows:

- convection chamber

- furnace chamber

- Waste heat recovery system

- ventilation system

- combustor

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

A space for holding metallic materials for heating.

Recover the waste heat in the exhaust gas of heating furnace to improve the energy utilization efficiency.

Ensure the gas flow in the furnace and maintain the stability of the atmosphere and temperature in the furnace.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Direct heating annealing furnace

5、How much is the Direct heating annealing furnace?

The Direct heating annealing furnace price is introduced as follows:

- regional difference

- Model size

- product function

- market factors

- technology content

The consumption level in different regions is different, which directly affects the equipment cost investment. Generally speaking, the higher the consumption level, the higher the cost of production equipment, and the higher the cost investment, the higher the price naturally.

The same product, even with different specifications and models and different configurations, has different costs, so the price will be different.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The market has great fluctuation, which is also the key factor that leads to the imbalance and instability of supply and demand, and then leads to great changes in product prices. Only after a comprehensive understanding and investigation of the market can we make a reasonable decision, and then we can formulate a Direct heating annealing furnace price sales plan that customers are satisfied with, and the main reason for its price rationality is also reflected here.

Each customer needs different products, wants to achieve different purposes, and has different product technical design. The higher or more advanced the technical requirements, the more the product cost will be, and the price will increase with the increase of cost. On the contrary, the price will be cheaper.

Direct heating annealing furnace

6、One-combustion energy saving delivery site

Speak directly with facts on the spot。

Direct heating annealing furnace

As you can see from the live video.One-combustion energy saving is a popular Direct heating annealing furnace。

Direct heating annealing furnaceThe high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,Easy to maintain,Easy to control,Strong adaptability,energy-efficient,Stable and reliable,Simple structure and reliable operation.,structure mainly includes: recovery of waste heat, Radiation chamber, ventilation system, furnace chamber, ventilation system and so on。

Related recommendation

-

What is a Low temperature catalytic reduction flue gas denitrification system? Introduction to the advantages and characteristics of the SCR denitration

2025-5-27 -

Brief introduction of Pull rod annealing industrial furnace

2025-6-18 -

Introduction to SCR Low Temperature Flue Gas Denitrification System and SCR flue gas denitrification structure principle

2025-5-27 -

Introduction to Continuous roll quenching and tempering heat treatment furnace, Forging furnace specifications, model parameters

2025-5-27 -

What is a Forging quenching heat treatment furnace? How much is the price of the Forging furnace?

2025-5-27 -

Introduction to Intelligent electric furnace and Trolley electric heating furnace working principle

2025-5-27 -

What is a Continuous well quenching furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

环形天然气台车炉

2023-08-24 -

What is a Roll annealing furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Dual phase steel heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27