Introduction to Aluminum alloy heating furnace, forging furnace advantages, characteristics and principles

Aluminum alloy heating furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,Easy to maintain,Strong adaptability,Easy to control,energy-efficient,Strong adaptability,at runtime,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.,it can be used in Household necessities, heat treatment, Machinery manufacturing, building materials, war industry and other industries,low in price,modern technology。The following is to introduce the Aluminum alloy heating furnace:

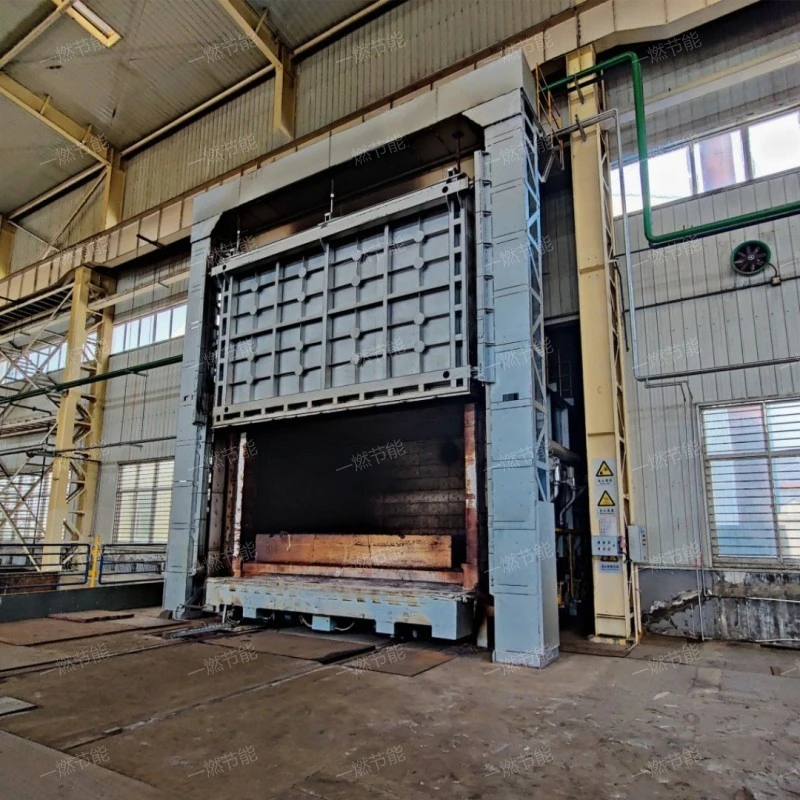

1、Brief introduction of Aluminum alloy heating furnace

Aluminum alloy heating furnaceIt is an important heating equipment before metal forging. It uses natural gas as fuel to heat metal materials through high-temperature flame and smoke generated by combustion to meet the requirements of forging process.,has been favored by more and more customers.。

Aluminum alloy heating furnace

2、Aluminum alloy heating furnace use

The purpose of Aluminum alloy heating furnace is introduced as follows:

- Energy conservation and environmental protection

- Metal heat treatment

- Metal tempering

- Improve production efficiency

- Metal forging heating

The Aluminum alloy heating furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

In addition to forging heating, Aluminum alloy heating furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Aluminum alloy heating furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Aluminum alloy heating furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

The Aluminum alloy heating furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

Aluminum alloy heating furnace

3、Working principle of Aluminum alloy heating furnace

Aluminum alloy heating furnaceat the start of the operation,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,it is widely used in surface treatment, automobile, war industry, chemical industry and building materials,It can be used for Metal heat treatment, Metal melting and casting, Energy conservation and environmental protection, Metal forging heating, Metal heat treatment, Metal forging heating and so on。

Aluminum alloy heating furnace

4、Aluminum alloy heating furnace function

Aluminum alloy heating furnaceit has the functions of quench, normalizing, temper, hardening and tempering and heat treatment,is a kind of high quality and low price Aluminum alloy heating furnace,can be customized according to user's needs.。

Aluminum alloy heating furnace

5、How much is the Aluminum alloy heating furnace?

The Aluminum alloy heating furnace price is introduced as follows:

- market factors

- product function

- Model size

- Configuration level

- sales mode

This is one of the external factors that lead to price fluctuation. Only after fully understanding the market can we make a reasonable decision. One-combustion energy saving has a deep understanding of this factor, so the price of our Aluminum alloy heating furnace is more reasonable.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The prices of products with different specifications and models will definitely be different. Generally speaking, the larger the specifications and models, the higher the prices will be. Because the raw materials and time consumed in the manufacturing process of large-sized products are more, the prices are much higher than those of small-sized products.

The difference in Aluminum alloy heating furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

One-combustion energy saving has long used the sales method of small profits but quick turnover to sell products, and the product price, market price and ex-factory price are the same. The purpose of this is to improve the sales volume of products and the visibility of enterprises.

Aluminum alloy heating furnace

6、company strength

The company has many years of Aluminum alloy heating furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Aluminum alloy heating furnacewidely used in pharmacy, machinery, petroleum, chemical industry, aerospace and other fields,The overall structural design is relatively simple and compact.,the main structure includes convection chamber, ventilation system, ventilation system, ventilation system, recovery of waste heat and so on,multifunctional, with functions such as Casting heating, Forging heating, anneal, quench and temper。

Related recommendation

-

Introduction to Natural gas trolley furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Combination walking heat treatment furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Multi functional tubular roaster, advantages, characteristics and principles of Forging furnace

2025-5-27 -

台车式连续退火炉

2023-07-12 -

Introduction to Double ended trolley heating furnace, Forging furnace specifications, model parameters

2025-5-27 -

Introduction to Gas trolley forging furnace and forging furnace advantages and features

2025-5-27 -

What is a Regenerative natural gas through forging heating furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27 -

Introduction to Trolley type tempering furnace and heating furnace working principle

2025-5-27 -

What is a Stress relief annealing heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

What is a Roll trolley forging furnace? Introduction to the advantages, characteristics, and principles of the forging furnace

2025-5-27