What is a Catalyst oxidation flue gas denitrification? Introduction to the principle of SCR flue gas denitrification structure

Catalyst oxidation flue gas denitrificationthe full name is selective catalytic reduction technology, which is an advanced flue gas denitrification technology.。The following is to introduce the Catalyst oxidation flue gas denitrification:

1、Brief introduction of Catalyst oxidation flue gas denitrification

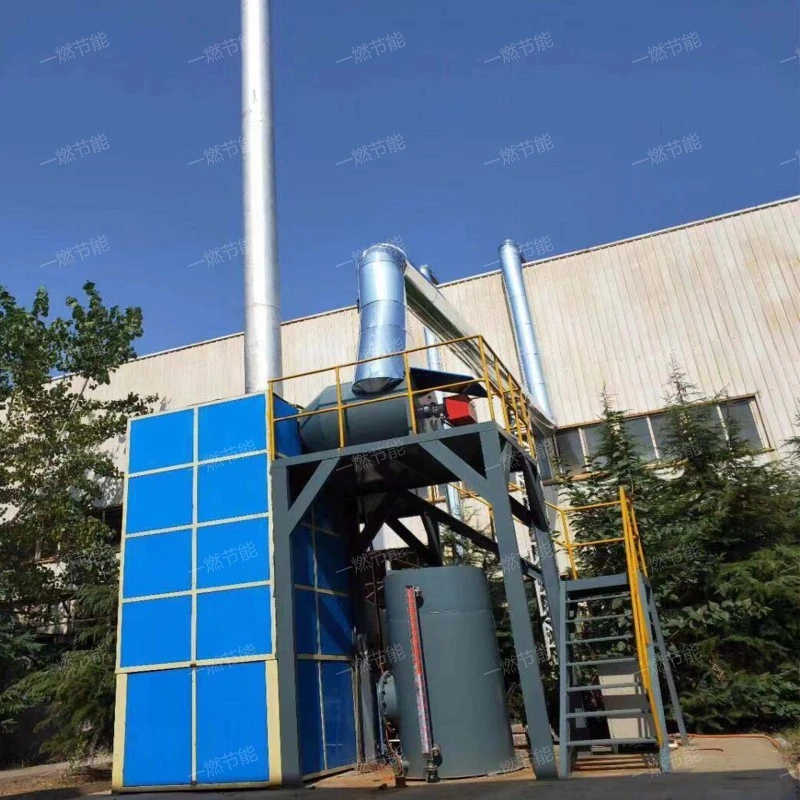

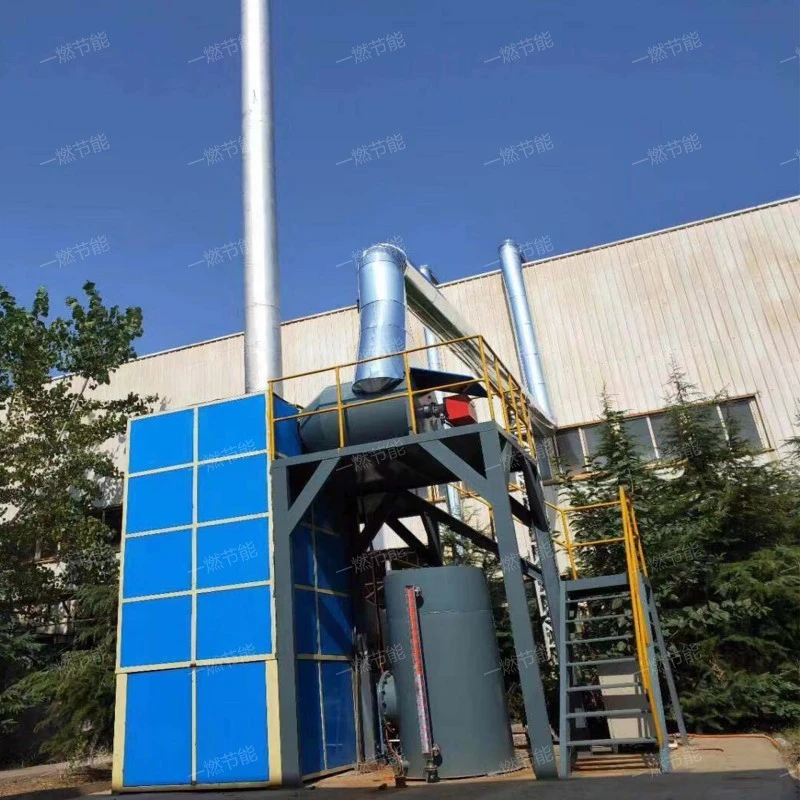

Catalyst oxidation flue gas denitrificationis an efficient, stable and environment-friendly flue gas denitrification technology.,the product looks beautiful.,is a kind of Catalyst oxidation flue gas denitrification manufactured by One-combustion energy saving。

Catalyst oxidation flue gas denitrification

2、Introduction of Catalyst oxidation flue gas denitrification characteristics

Catalyst oxidation flue gas denitrification has the following characteristics

- selectivity

- Stable operation and stability

- energy saving and environmental protection

- Strong adaptability

- Environmental protection

Under the action of catalyst, the reducing agent mainly reacts with NOx selectively, but less with other components (such as oxygen) in flue gas, thus reducing unnecessary consumption.

The Catalyst oxidation flue gas denitrification technology runs stably and can meet the requirements of flue gas treatment under different working conditions.

This technology can effectively reduce NOx emission in flue gas, reduce environmental pollution, and at the same time, it has stable operation and low energy consumption, which meets the requirements of energy saving and environmental protection.

Catalyst oxidation flue gas denitrification technology can meet the needs of flue gas denitrification under different working conditions and has a wide range of applications.

The final products of Catalyst oxidation flue gas denitrification technology are harmless nitrogen and water vapor, which will not cause secondary pollution to the environment.

Catalyst oxidation flue gas denitrification

3、Advantages of Catalyst oxidation flue gas denitrification principle

Catalyst oxidation flue gas denitrificationin the course of work,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,Cheap and high quality。

Catalyst oxidation flue gas denitrification

4、Catalyst oxidation flue gas denitrification video live broadcast

One-combustion energy saving provides customers with on-site high-definition video, fully demonstrates the advantages of on-site productt operation, and helps customers to deeply understand the product production process and production site, and gain favorable comments and recognition from customers.。

Catalyst oxidation flue gas denitrification

As you can see from the live video.,One-combustion energy saving it refers to the process of removing nitrogen oxides from flue gas to reduce environmental pollution. NOx is a pollutant harmful to the atmospheric environment, which has strong irritation and toxicity, and will lead to environmental problems such as acid rain and photochemical smog, and also endanger human health. The main principle of flue gas denitrification technology is to reduce NOx to nitrogen and water by adding appropriate reducing agent or catalyst in the combustion process or flue gas treatment system, so as to reduce NOx emission.。

5、Catalyst oxidation flue gas denitrification price consultation

The Catalyst oxidation flue gas denitrification price is introduced as follows:

- regional difference

- product function

- select a qualified person

- regional advantages

- market demand

There are differences in consumption levels in different regions, which directly affect the production and manufacturing costs of products. Generally speaking, the higher the consumption level, the higher the cost of producing products, and the higher the product cost, the higher the price naturally.

The more functions a product has, the higher its manufacturing cost, so that the product can be used by customers as much as possible, which can create more useful value for customers, so the price will be higher.

The higher the cost of materials, the higher the price will be. In the process of purchasing products, users need to make a detailed understanding of the materials selected for products.

One-combustion energy saving address:Jinan, the transportation here is developed and convenient, and the products can be transported to the designated place in a short time, which saves customers a sum of transportation expenses.

The difference between the supply and demand of manufacturers and customers will also affect the Catalyst oxidation flue gas denitrification price. When the demand of customers on the market increases and the supply of products by manufacturers is small, the Catalyst oxidation flue gas denitrification price will increase with the increase of demand. On the contrary, when the supply of product manufacturers on the market exceeds the demand of customers, the Catalyst oxidation flue gas denitrification price will decrease.

Catalyst oxidation flue gas denitrification

6、One-combustion energy saving after-sales service

Perfect service: In order to improve the service quality and improve the service level, One-combustion energy saving has set up a sound quality management department and a professional after-sales service team, so as to be highly responsible for customers and avoid their worries in the use process.。

One-combustion energy saving

Catalyst oxidation flue gas denitrificationIt can be used for Improve product quality, environmental protection, Promote sustainable development, Meet the requirements of environmental protection, Meet the requirements of environmental protection, Promote sustainable development and so on,at work,Under the action of catalyst, reducing agents (such as ammonia, urea, etc.) react with nitrogen oxides in flue gas to convert them into harmless nitrogen and water vapor.,the product looks atmospheric.。

Related recommendation

-

What is a Catalytic reduction denitrification system? Introduction to the advantages, characteristics, and principles of the SCR denitration system

2025-5-27 -

What is a Chain belt quenching heat treatment furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Stress relief annealing heating furnace? Introduction to the Working Principle of heating furnace

2025-5-27 -

Introduction to Energy saving trolley forging heating furnace, introduction to heating furnace function advantages and characteristics

2025-5-27 -

Introduction to Side door trolley forging heating furnace and Forging furnace working principle

2025-5-27 -

Introduction to Natural gas boiler flue gas denitrification equipment and SCR denitration system structure principle

2025-5-27 -

Introduction to Continuous gas trolley furnace and forging furnace working principle

2025-5-27 -

轨道天然气台车炉

2023-08-18 -

某盾构机刀圈锻造炉案例

2023-04-16 -

Introduction to Thermal insulation and tempering industrial furnace and Forging furnace structure principle

2025-5-27