Introduction to Quenching and tempering well type annealing furnace, how much is the price of the forging furnace?

Quenching and tempering well type annealing furnaceIt is a forging heating device using gas as fuel.,it can be used in heat treatment, material, automobile, Household necessities, building materials and other industries。

1、Brief introduction of Quenching and tempering well type annealing furnace

Quenching and tempering well type annealing furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,it has the characteristics of energy saving and environmental protection, Stable and reliable, energy-efficient, energy saving and environmental protection and Strong adaptability,it is an ideal choice for customers to buy Quenching and tempering well type annealing furnace。

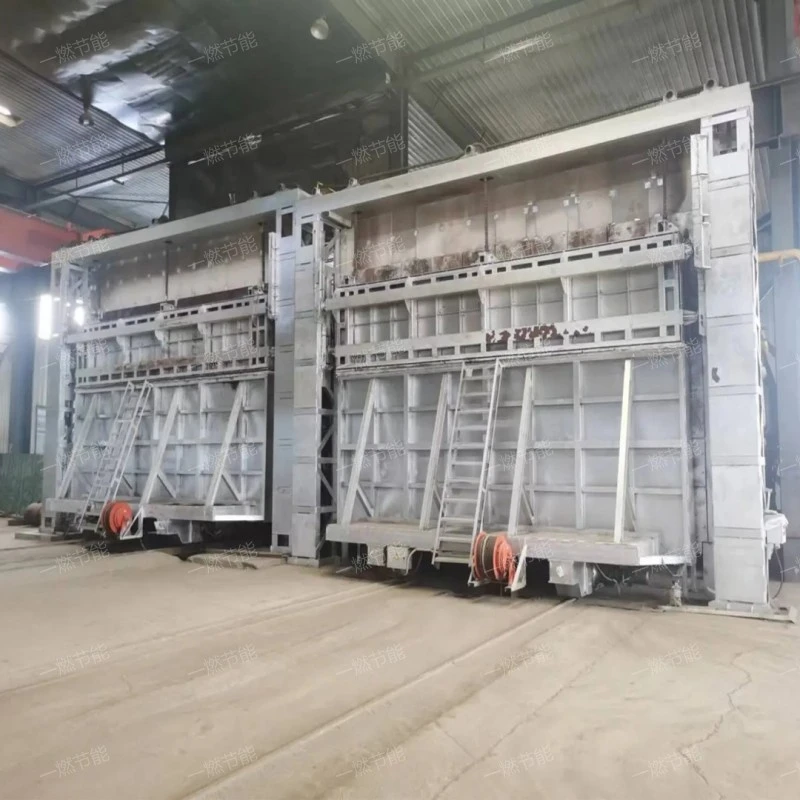

Quenching and tempering well type annealing furnace

2、Functional advantages of Quenching and tempering well type annealing furnace

Quenching and tempering well type annealing furnaces have the following advantages.

- Improve product quality

- Efficient combustion

- Intelligent control

- Rapid temperature rise

- Extend the service life of equipment

Because the Quenching and tempering well type annealing furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

The Quenching and tempering well type annealing furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Quenching and tempering well type annealing furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The Quenching and tempering well type annealing furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

The Quenching and tempering well type annealing furnace adopts advanced combustion technology and materials, which has a long service life and low maintenance cost.

Quenching and tempering well type annealing furnace

3、Quenching and tempering well type annealing furnace function

Quenching and tempering well type annealing furnaceit has the functions of heat treatment, hardening and tempering, anneal, temper and heat treatment,It is mostly used in Metal tempering, Metal melting and casting, Metal forging heating, Improve production efficiency, Metal heat treatment, Energy conservation and environmental protection and so on,is a popular Quenching and tempering well type annealing furnace,has been favored by more and more customers.。

Quenching and tempering well type annealing furnace

4、Advantages of Quenching and tempering well type annealing furnace principle

Quenching and tempering well type annealing furnaceHeat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,is carefully developed by One-combustion energy saving combined with advanced technology。

Quenching and tempering well type annealing furnace

5、Working principle of Quenching and tempering well type annealing furnace

Quenching and tempering well type annealing furnaceat work,The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Quenching and tempering well type annealing furnace

Quenching and tempering well type annealing furnaceat runtime,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,multifunctional, with functions such as Casting heating, Forging heating, normalizing, quench and hardening and tempering。

Related recommendation

-

What is a SCR catalytic oxidation denitrification? Introduction to the advantages and characteristics of SCR denitration functions

2025-5-27 -

What is a Kiln car trolley heating furnace? Introduction to the advantages and characteristics of the heating furnace

2025-5-27 -

Introduction to Annular well tube furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

Introduction to Regenerative natural gas chamber furnace, introduction to heating furnace advantages and characteristics

2025-5-27 -

Introduction to Metal industry electric furnace, advantages, characteristics and principles of Trolley electric furnace

2025-5-27 -

What is a Roller shaft quenching and tempering heat treatment furnace? Introduction to the advantages and characteristics of the forging furnace

2025-5-27 -

What is a Preheating burner trolley forging heating furnace? Introduction to the advantages and characteristics of Forging furnace functions

2025-5-27 -

What is a Quenching natural gas trolley furnace? How much is the price of the heating furnace?

2025-5-27 -

Introduction to Kiln car trolley furnace, Forging furnace advantages, characteristics and principles

2025-5-27 -

台车热处理炉

2023-04-25