Introduction to Chain grate heat treatment furnace, introduction to forging furnace function advantages and characteristics

Chain grate heat treatment furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,The high-temperature flame and flue gas generated when the fuel burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature. Fuel is ejected from the burner and burned, resulting in high-temperature flame and high-temperature flue gas. The high-temperature flame transfers heat to the furnace tube in the radiation chamber through radiation, and then to the medium in the furnace tube. The high-temperature flue gas enters the convection chamber of the heating furnace upward due to the suction force of the chimney or the action of the induced draft fan, and the heat is transferred to the furnace tube in the convection chamber by convection, and then to the medium in the furnace tube.,Widely used inImprove production efficiency,Metal heat treatment,Improve production efficiency,Energy conservation and environmental protection,Metal tempering and so on,the product looks atmospheric.,the advantage is Adopting advanced combustion technology and control system can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、Natural gas is mainly used as fuel, but some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.、Uniform heating and precise control can be realized, so it is helpful to improve the product quality and yield of metal materials.、Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.。

1、Brief introduction of Chain grate heat treatment furnace

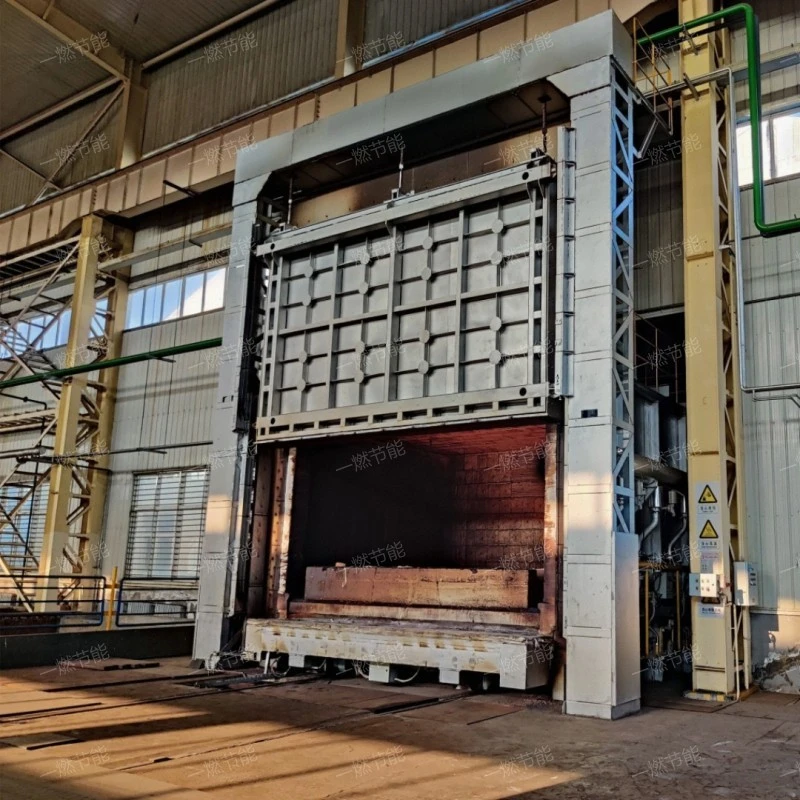

Chain grate heat treatment furnaceIt is a forging heating device using gas as fuel.,at work,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.。

Chain grate heat treatment furnace

2、Chain grate heat treatment furnace performance advantage

Chain grate heat treatment furnaces have the following advantages.

- Intelligent control

- Efficient combustion

- easy to operate

- Rapid temperature rise

- Multiple fuel options

The Chain grate heat treatment furnace is usually equipped with an intelligent control system, which can automatically adjust the parameters such as gas supply and air flow according to the heating demand, and realize accurate control of the temperature and atmosphere in the furnace.

The Chain grate heat treatment furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The operation interface of the Chain grate heat treatment furnace is friendly and easy for operators to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.

The Chain grate heat treatment furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

Although the Chain grate heat treatment furnace mainly uses natural gas as fuel, some equipment also supports other types of gas or liquid fuel, which has strong fuel adaptability.

Chain grate heat treatment furnace

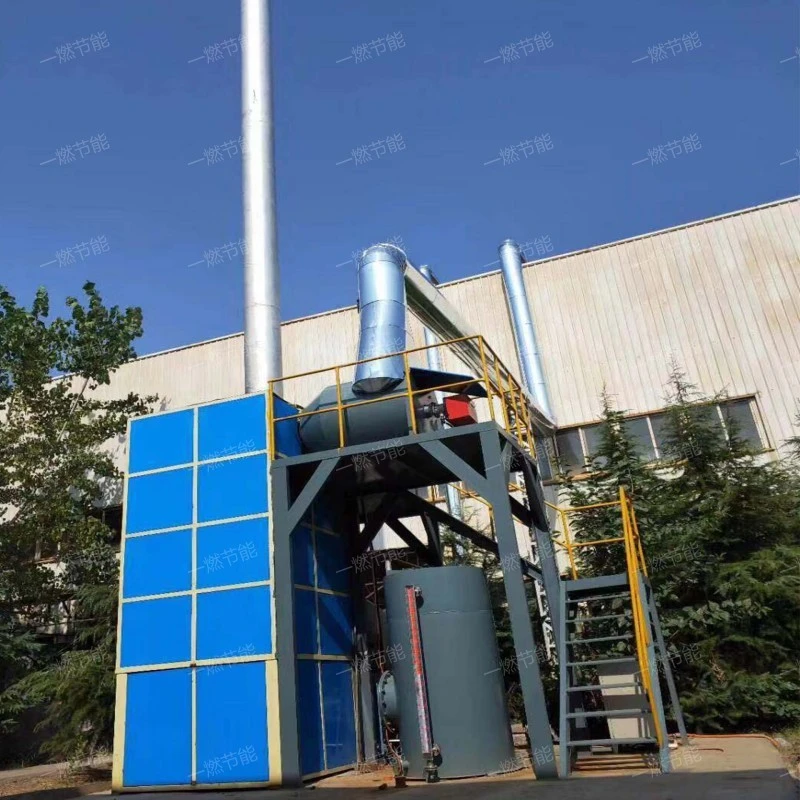

3、Chain grate heat treatment furnace HD picture real shot

Chain grate heat treatment furnace HD real shot, a variety of specifications and models display, for our customers to choose at will.。

Chain grate heat treatment furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Introduction of Chain grate heat treatment furnace characteristics

Chain grate heat treatment furnace has the following characteristics

- Stable and reliable

- Strong adaptability

- Easy to control

- Easy to control

- Stable and reliable

The Chain grate heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

The Chain grate heat treatment furnace can be used for forging and heating of bar, round steel, square steel, steel plate and other metal materials, and has a wide range of applications.

The combustion system and ventilation system of the Chain grate heat treatment furnace can be adjusted as required to accurately control the temperature and atmosphere in the furnace and meet the heating requirements of different metal materials.

By adjusting the burner and ventilation system, the temperature and atmosphere in the furnace can be accurately controlled to meet the heating requirements of different metal materials.

The Chain grate heat treatment furnace has a stable combustion system and temperature control system, which can ensure the uniformity and stability of the temperature in the furnace, thus improving the quality and production efficiency of forged products.

Chain grate heat treatment furnace

5、Chain grate heat treatment furnace application

Chain grate heat treatment furnaces have the following purposes.

- Metal heat treatment

- Metal tempering

- Energy conservation and environmental protection

- Metal forging heating

- Metal heat treatment

In addition to forging heating, Chain grate heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

By properly heating and cooling the metal material, the Chain grate heat treatment furnace can realize the quenching and tempering treatment of the metal. This is helpful to adjust the hardness and toughness of metal to meet the needs of different workpieces.

The Chain grate heat treatment furnace uses clean energy as fuel, which has lower emissions and higher energy efficiency than traditional coal-fired or oil-fired stoves. This is helpful to reduce environmental pollution and realize green production.

The Chain grate heat treatment furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

In addition to forging heating, Chain grate heat treatment furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

Chain grate heat treatment furnace

6、Chain grate heat treatment furnace price advantage

The Chain grate heat treatment furnace price is introduced as follows:

- market supply and demand

- After-sales service level

- Different regions

- select a qualified person

- quality

The amount of customers' demand for Chain grate heat treatment furnace in the market also has a great influence on the price. When there are many customers purchasing this product in the market and the supply quantity of manufacturers is small, the Chain grate heat treatment furnace price will be very high. On the contrary, when fewer customers purchase this product, there will be a phenomenon of oversupply, and the price of Chain grate heat treatment furnace will naturally be reduced.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Chain grate heat treatment furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Chain grate heat treatment furnace price can meet the purchasing needs of customers.

Different provinces and regions have different consumption levels, different market positioning and different prices.

Different manufacturers have different material selection standards. The better the quality of the selected materials, the more expensive the products will be. On the contrary, the prices will be low. However, to avoid customers being deceived, compare several products of the same specification and model before deciding to purchase.

If the quality of the product is guaranteed, its service life will be longer. At the same time, the more perfect the performance, the more economic value can be created for customers, and the price of such products will be higher. One-combustion energy saving has strictly controlled the quality and the sales price is also reasonable.

Chain grate heat treatment furnace

Chain grate heat treatment furnacethe product looks beautiful.,is a common Chain grate heat treatment furnace。

Related recommendation

-

Introduction to Baking furnace chamber type, forging furnace specifications, model parameters

2025-5-27 -

Introduction to Intelligent trolley forging heating furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

Introduction to Carburizing and normalizing industrial furnace and Forging furnace advantages and features

2025-5-27 -

Introduction to Regenerative gas chamber heating furnace, how much is the price of the heating furnace?

2025-5-27 -

Introduction to Low temperature catalytic reduction denitrification, SCR denitration specifications, model parameters

2025-5-27 -

What is a Roller type annealing furnace? Introduction to the advantages, characteristics, and principles of the heating furnace

2025-5-27 -

What is a Forging trolley forging furnace? forging furnace specifications, models, and parameters

2025-5-27 -

What is a Trolley industrial electric furnace? Introduction to the Working Principle of Trolley electric furnace

2025-5-27 -

Introduction to Double door quenching natural gas trolley furnace, heating furnace specifications, model parameters

2025-5-27 -

Introduction to Tubular continuous heating furnace, how much is the price of the heating furnace?

2025-5-27