Introduction to Stepping bottom industrial furnace, heating furnace advantages, characteristics and principles

Stepping bottom industrial furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,The overall structural design is simple and novel.,it is usually composed of convection chamber, Radiation chamber, furnace chamber, ventilation system and recovery of waste heat,it has the functions of quench, anneal, Forging heating, hardening and tempering and quench。

1、Brief introduction of Stepping bottom industrial furnace

Stepping bottom industrial furnaceIt is a kind of heating equipment using natural gas as fuel, which is mainly used to heat metal materials to the required forging temperature in a short time.,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,the product looks atmospheric.,can be customized according to user's needs.。

Stepping bottom industrial furnace

2、Stepping bottom industrial furnace application

Stepping bottom industrial furnaces have the following purposes.

- Improve production efficiency

- Metal melting and casting

- Metal heat treatment

- Metal forging heating

- Improve production efficiency

The Stepping bottom industrial furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Although it is mainly used for forging heating, some types of Stepping bottom industrial furnaces can also be used in metal melting and casting processes. This is especially suitable for melting and casting of small or special alloys.

In addition to forging heating, Stepping bottom industrial furnaces can also be used for metal heat treatment processes, such as annealing and tempering. These processes can improve the microstructure and properties of metal materials, and improve their service life and mechanical properties.

The Stepping bottom industrial furnace can heat the metal material to the temperature required for forging, improve its plasticity and fluidity, and thus facilitate forging. This is very important for the forging of various metal materials.

The Stepping bottom industrial furnace has the advantages of fast heating speed and accurate temperature control, which can improve production efficiency. This is especially important for mass-produced forging workshops.

Stepping bottom industrial furnace

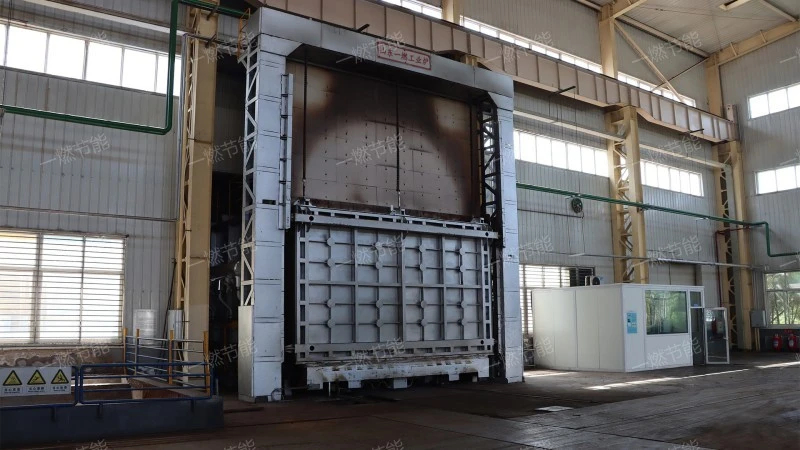

3、Stepping bottom industrial furnace field real shot

High-definition picture display of Stepping bottom industrial furnace, excellent material selection, reliable quality and trustworthy.。

Stepping bottom industrial furnace

Note: All the pictures in this article were taken by One-combustion energy saving manufacturer.。

4、Stepping bottom industrial furnace principle

Stepping bottom industrial furnacethe principle is simple.Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,the product looks atmospheric.,It is a forging heating device using gas as fuel.,be loved by our customers.。

Stepping bottom industrial furnace

5、Structural characteristics of Stepping bottom industrial furnace

The Stepping bottom industrial furnace has the following structure

- Waste heat recovery system

- convection chamber

- Radiation chamber

- furnace chamber

- combustor

Used to recover the exhaust heat of the heating furnace. There are two kinds of recovery methods, one is to recover by preheating combustion air, so that the recovered heat can return to the furnace again; The other is to use another recovery system to recover heat. The former is called air preheating mode, and the latter is usually called waste heat boiler mode.

The high-temperature flue gas discharged from the radiation chamber is used for convective heat transfer to further heat the metal materials.

The heat load of the main place for Stepping bottom industrial furnace heat exchange accounts for about 70%-80% of the whole furnace. The furnace tube in the radiation room conducts heat through flame or high-temperature flue gas, which is mainly radiant heat, so it is called radiation tube.

A space for holding metallic materials for heating.

The device that mixes natural gas with combustion-supporting air and ejects it is the core component of the heating furnace.

Stepping bottom industrial furnace

6、Stepping bottom industrial furnace price concessions

The Stepping bottom industrial furnace price is introduced as follows:

- Cost input

- deploy

- Company size

- Model size

- technology content

The manufacturer has a fixed raw material supplier, so that the raw material price given by the raw material supplier to the manufacturer will be lower, the raw material cost invested by the manufacturer will be reduced, and the price of the Stepping bottom industrial furnace will also be reduced.

The difference in Stepping bottom industrial furnace configuration will affect the product cost price. The higher the configuration, the higher the product cost price and the higher the overall selling price of the product. It is suggested that customers should compare whether the configuration is in line with the quotation when purchasing products, and compare more companies.

There are many manufacturers of products in Jinan, and the strength, technology and after-sales of each manufacturer are different, so the quotation for Stepping bottom industrial furnace is naturally different.

One-combustion energy saving Stepping bottom industrial furnace has various specifications and models, and the prices of different specifications and models are also different. The main difference lies in the different technologies used in the products and the different manufacturing costs. One-combustion energy saving Sell products at lower prices, so that every customer can enjoy preferential prices

The more advanced the technology, the higher the price will be, otherwise the product price will be low, and customers must pay attention to whether their own technology meets the production requirements when purchasing products.

Stepping bottom industrial furnace

Stepping bottom industrial furnacemultifunctional, with functions such as hardening and tempering, heat treatment, normalizing, anneal and Forging heating,structure mainly includes: convection chamber, ventilation system, combustor, ventilation system, recovery of waste heat and so on,productThe overall structural design is relatively simple。

Related recommendation

-

What is a Chain plate heating furnace? Introduction to the principle of heating furnace structure

2025-5-27 -

Introduction to Roller bottom continuous heating furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Round tube roasting furnace, advantages, characteristics and principles of Forging furnace

2025-5-27 -

What is a Multi functional continuous heat treatment industrial furnace? Forging furnace specifications, models, and parameters

2025-5-27 -

What is a Trolley forging heating resistance furnace? Trolley resistance furnace specifications, models, and parameters

2025-5-27 -

Introduction to Oxidation reduction method for denitrification, SCR denitration advantages, characteristics and principles

2025-5-27 -

What is a Chain type heating furnace? How much is the price of the Forging furnace?

2025-5-27 -

Introduction to Metal trolley forging furnace, introduction to forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Trolley insulation heating furnace, heating furnace specifications, model parameters

2025-5-27 -

台车式工业退火炉

2023-07-07