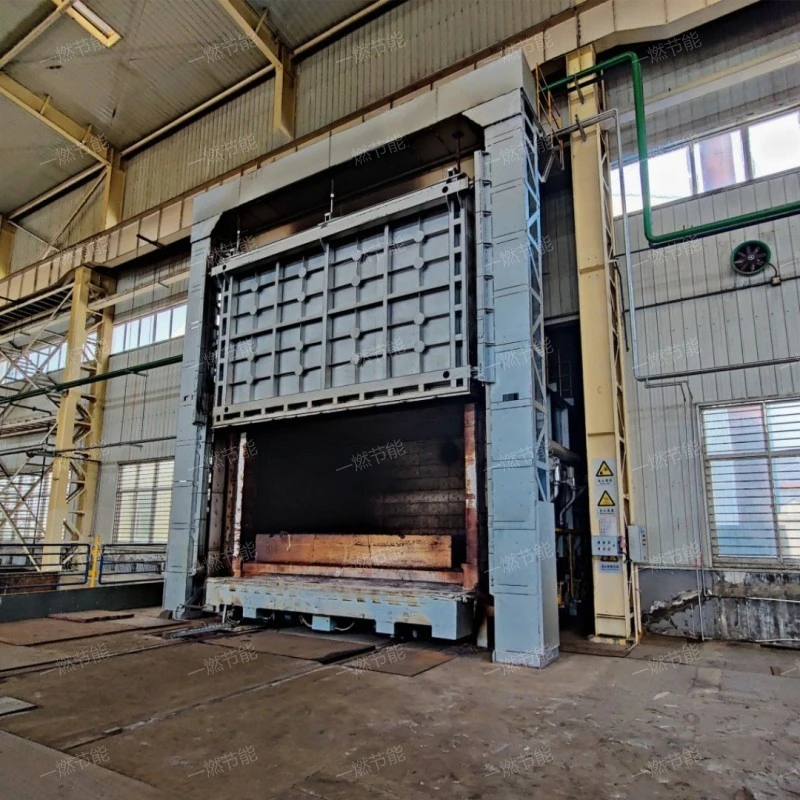

Introduction to Fully automatic trolley forging furnace, forging furnace specifications, model parameters

Fully automatic trolley forging furnaceIt is a kind of equipment which uses gas as fuel and is specially used for heating metal before forging.,is a popular Fully automatic trolley forging furnace,Heat of combustion based on fuel. Natural gas is sprayed from the burner, mixed with combustion-supporting air and burned to produce high-temperature flame and smoke. These high-temperature flames and smoke transfer heat to the metal materials in the furnace by radiation and convection, so that they gradually heat up to the temperature required for forging.,is designed by One-combustion energy saving with advanced technology。

1、Brief introduction of Fully automatic trolley forging furnace

Fully automatic trolley forging furnaceIt is an efficient, energy-saving and environment-friendly metal heating device.,is a kind of Fully automatic trolley forging furnace manufactured by One-combustion energy saving。

Fully automatic trolley forging furnace

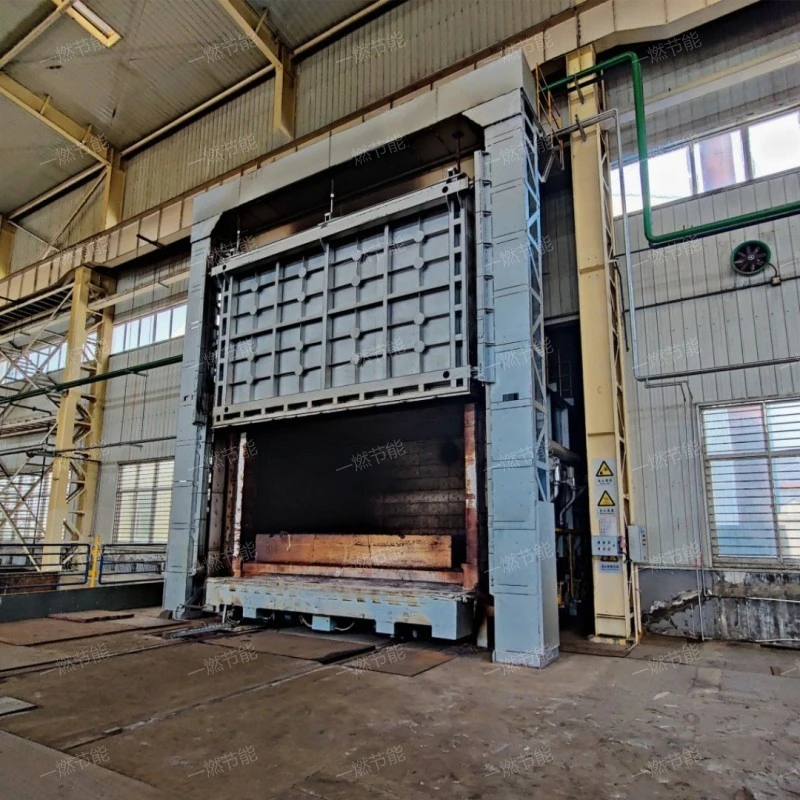

2、Video analysis of Fully automatic trolley forging furnace

Speak directly with facts on the spot。

Fully automatic trolley forging furnace

As you can see from the live video.,One-combustion energy saving the main features are Easy to maintain, Easy to control, Stable and reliable, Easy to maintain and energy saving and environmental protection。

3、Fully automatic trolley forging furnace performance advantage

The advantages of Fully automatic trolley forging furnace are as follows:

- Reduce operating costs

- Efficient combustion

- Uniform heating

- Improve product quality

- Rapid temperature rise

The efficient combustion and waste heat recovery system of the Fully automatic trolley forging furnace can significantly reduce energy consumption, thus reducing operating costs.

The Fully automatic trolley forging furnace adopts advanced combustion technology and control system, which can realize full combustion of natural gas and improve combustion efficiency. At the same time, some equipment is also equipped with waste heat recovery system, which can further recycle the waste heat in exhaust smoke and improve energy utilization efficiency.

The Fully automatic trolley forging furnace adopts regenerative combustion system or advanced burner design, which can realize uniform distribution of temperature in the furnace, ensure uniform heating of metal materials and improve product quality.

Because the Fully automatic trolley forging furnace can realize uniform heating and precise control, it is helpful to improve the product quality and yield of metal materials.

The Fully automatic trolley forging furnace can heat the metal material to the required temperature in a short time, which improves the production efficiency.

Fully automatic trolley forging furnace

4、Advantages of Fully automatic trolley forging furnace principle

Fully automatic trolley forging furnaceat runtime,Heat of combustion based on fuel. Fuel gas (such as natural gas, liquefied petroleum gas, etc.) is mixed with combustion-supporting air through the burner and burned to produce high-temperature flame and flue gas. These high-temperature flames and smoke exchange heat with metal materials in the furnace, so that they gradually heat up to the temperature required for forging.,is a common Fully automatic trolley forging furnace,was developed and designed by One-combustion energy saving。

Fully automatic trolley forging furnace

5、Fully automatic trolley forging furnace price advantage

The Fully automatic trolley forging furnace price is introduced as follows:

- market demand

- brand

- After-sales service level

- model

- cost of production

This is one of the external factors that lead to price fluctuation. Only after fully understanding the market can we make a reasonable decision. One-combustion energy saving has a deep understanding of this factor, so the price of our Fully automatic trolley forging furnace is more reasonable.

Different brands of products in the same series have more or less differences in product prices, and different brands of Fully automatic trolley forging furnace have more or less differences in price.

There is a close relationship between service and price. High-quality service can not only avoid all worries in the process of product use, but also improve the overall strength and comprehensive credibility of manufacturers. In order to improve the service quality, One-combustion energy saving Fully automatic trolley forging furnace manufacturers provide comprehensive services for customers and products before, during and after sale, and at the same time make the price as favorable as possible to new and old customers, so that the Fully automatic trolley forging furnace price can meet the purchasing needs of customers.

There are many product specifications and models in the market. The efficiency and power of different specifications and models are different, and the price is naturally different. Customers need to choose the appropriate specifications and models according to their own needs.

If the cost of the product is high, the selling price of the product will be high, so the cost input is an important factor that causes the price change of the Fully automatic trolley forging furnace.

Fully automatic trolley forging furnace

6、company strength

The company has many years of Fully automatic trolley forging furnace manufacturing experience, large scale and strong strength.。

One-combustion energy saving

Fully automatic trolley forging furnacethe advantage is Using regenerative combustion system or advanced burner design can realize the uniform distribution of temperature in the furnace, ensure the uniform heating of metal materials and improve product quality.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、The user interface is friendly, and the operator is easy to use. At the same time, the equipment also has the function of fault diagnosis and alarm, which can find and deal with abnormal situations in time.、It has the advantages of high heating efficiency, high energy utilization, accurate temperature control, good environmental protection performance, simple operation and strong adaptability.、It can improve the plasticity and fluidity of metal materials, reduce the difficulty and cost of forging, and improve product quality and production efficiency.,the principle is simple.The high-temperature flame and flue gas generated when fuel (natural gas) burns in the furnace are used as heat sources to heat the medium flowing in the tube to reach the specified process temperature.。

Related recommendation

-

Introduction to High temperature carburizing heat treatment heating furnace and forging furnace advantages and features

2025-5-27 -

What is a Low temperature absorption SCR denitrification? SCR denitration specifications, models, and parameters

2025-5-27 -

Introduction to High temperature tube heating furnace and heating furnace structure principle

2025-5-27 -

Introduction to Roller type solid solution quenching furnace, advantages, characteristics and principles of heating furnace

2025-5-27 -

回火台车锻造炉

2023-08-28 -

Introduction to Fully automatic industrial furnace, introduction to Forging furnace advantages and characteristics

2025-5-27 -

Introduction to Continuous heat treatment industrial furnace, introduction to Forging furnace function advantages and characteristics

2025-5-27 -

Introduction to Double door well quenching furnace, how much is the price of the Forging furnace?

2025-5-27 -

What is a Low temperature catalyst furnace external flue gas denitrification system? Introduction to the Working Principle of SCR denitration system

2025-5-27 -

What is a Energy saving and environmentally friendly tube furnace? How much is the price of the heating furnace?

2025-5-27